Could your golf cart silently expose you to a deadly gas? Many assume all batteries produce carbon monoxide like car engines, but the reality defies expectations.

Unlike combustion engines that burn fuel, golf cart batteries—whether lead-acid or lithium-ion—operate through electrochemical reactions that do not generate this toxic gas. However, improper charging setups can create hidden risks you’d never anticipate.

Imagine parking your cart in a closed garage after a round. While the battery itself poses no CO threat, charging it without ventilation may trigger hydrogen gas buildup, a lesser-known hazard.

Best Golf Cart Batteries for Safe and Efficient Performance

Trojan T-1275 12V 150Ah Flooded Lead Acid GC12 Deep Cycle Battery

A trusted industry leader, the Trojan T-1275 delivers reliable power for 36V and 48V golf carts. Its thick plates and durable construction ensure a long lifespan (up to 1,200 cycles) and consistent performance. Flooded lead-acid design requires maintenance but offers affordability and proven safety with zero CO emissions.

- Trojan T-1275 Deep-Cycle Flooded/Wet Lead-Acid Battery

- This is the 150Ah, 12-volt deep cycle battery from Trojan. These can be…

- BCI Group Size: GC12 – Dimensions: Length: 12.96” (329mm); Width: 7.13”…

ECO-WORTHY 48V 100Ah Lifepo4 Lithium-Ion Battery

For a maintenance-free, high-efficiency option, the Eco Battery 48V 100Ah lithium pack excels. Lightweight (70% smaller than lead-acid) and with a 5,000-cycle lifespan, it includes built-in battery management (BMS) to prevent overheating. No hydrogen off-gassing makes it ideal for enclosed spaces.

- Upgraded to Cubix 100 (Feb 5, 2026) – The ECO-WORTHY 48V 100Ah Server…

- Closed-Loop Communication Battery: ECO-WORTHY 48V (51.2V) server rack…

- Space-Saving Rack Design: This 48V 100AH lithium battery is perfectly…

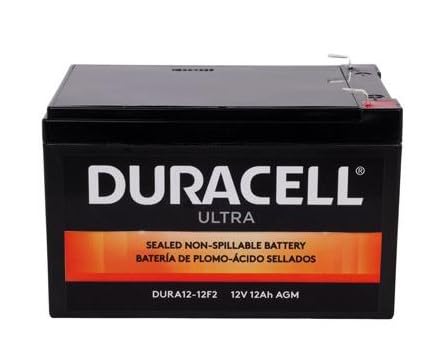

Duracell Ultra 12V 12AH AGM Sealed Lead Acid

The Duracell Ultra 12V 12AH AGM Sealed Lead Acid combines sealed AGM safety with deep-cycle endurance. Spill-proof and vibration-resistant, it eliminates hydrogen venting risks during charging. Ideal for golfers prioritizing hassle-free operation and enhanced durability in extreme temperatures.

- DURA12-12F2 – Is an interchange/replacement for competitive part number…

- 5.94 in Width: 3.86 in Height: 3.86 in – make sure to measure your space!

- Equipped with F2, T2, Faston .250 terminals to fit a variety of…

How Golf Cart Batteries Work and Why They Don’t Emit Carbon Monoxide

Unlike gasoline engines that burn fuel and produce exhaust gases, golf cart batteries generate power through electrochemical reactions—a process that fundamentally prevents carbon monoxide (CO) emissions.

Whether using traditional lead-acid or modern lithium-ion batteries, the energy is stored and released without combustion. Here’s how each type operates safely:

Lead-Acid Batteries: Electrolysis Without Combustion

Flooded lead-acid batteries (like the Trojan T-1275) contain lead plates submerged in sulfuric acid. When discharging, a chemical reaction between the plates and electrolyte produces electricity—no burning occurs. During charging, electrolysis splits water into hydrogen and oxygen gas, but these are vented safely and pose no CO risk.

However, poor ventilation can allow hydrogen to accumulate, creating explosion hazards—a critical reason why charging areas need airflow.

Lithium-Ion Batteries: Sealed and Emission-Free

Lithium-ion models (such as the Eco Battery 48V) rely on lithium compounds moving between electrodes. Their sealed design eliminates gas venting entirely, making them safer for indoor storage.

Advanced battery management systems (BMS) monitor temperature and voltage, preventing overheating—a stark contrast to older battery technologies.

Common Misconceptions Debunked

- Myth: “All batteries emit CO like car exhaust.” Reality: Only combustion processes create CO. Batteries produce electricity chemically.

- Myth: “Charging golf carts indoors is always dangerous.” Reality: Lithium batteries can charge indoors, but lead-acid models need ventilation to disperse hydrogen.

Real-World Example: A golf course maintenance team stored carts in a sealed shed, noticing dizziness among staff. While CO detectors showed no alerts, hydrogen buildup from lead-acid charging was the culprit—highlighting why proper ventilation matters even without CO risks.

Understanding these mechanisms helps users mitigate real hazards (like hydrogen accumulation) while dismissing unfounded fears about carbon monoxide. Always prioritize manufacturer guidelines for charging environments.

Potential Hazards and Safety Measures for Golf Cart Battery Usage

While golf cart batteries don’t emit carbon monoxide, they present other safety considerations that demand attention. Understanding these risks and implementing proper precautions ensures safe operation and extends battery life.

Hydrogen Gas Accumulation During Charging

Lead-acid batteries produce hydrogen gas as a normal byproduct of charging, particularly during the final stages. In confined spaces, hydrogen concentrations can reach explosive levels (4-74% in air). A golf cart charging in a 10×10 foot garage can produce enough hydrogen to become dangerous within just 4-6 hours of charging.

Safety Protocol:

- Always charge in well-ventilated areas (minimum 5 air changes per hour)

- Keep charging stations at least 3 feet from walls and other equipment

- Install hydrogen detectors in permanent charging areas

- Never charge near open flames or sparks

Thermal Runaway in Lithium-Ion Batteries

While lithium batteries don’t vent gases, they can experience thermal runaway if damaged or improperly charged. This occurs when excessive heat causes a self-sustaining reaction, potentially leading to fires. The 2022 incident at a Florida golf resort where three lithium cart batteries caught fire demonstrates this risk.

Prevention Measures:

- Use only manufacturer-approved chargers with proper voltage regulation

- Inspect battery cases regularly for swelling or damage

- Store lithium batteries at 30-50% charge if not used for extended periods

- Install battery management systems (BMS) that monitor cell temperatures

Electrolyte Safety for Flooded Batteries

The sulfuric acid electrolyte in lead-acid batteries requires special handling. A common mistake is adding water before charging rather than after, which can cause electrolyte overflow. Always:

- Wear acid-resistant gloves and eye protection when servicing

- Use distilled water only, never tap water

- Maintain proper fluid levels (1/4″ above plates)

- Neutralize spills immediately with baking soda solution

Professional golf courses like Pebble Beach implement color-coded battery maintenance stations with these safety supplies readily available – a best practice worth emulating for any frequent user.

Battery Maintenance and Performance Optimization Strategies

Proper maintenance significantly impacts golf cart battery safety, lifespan, and performance. These professional-grade techniques apply differently to lead-acid and lithium-ion systems, requiring tailored approaches for each technology.

Lead-Acid Battery Maintenance Protocol

Flooded lead-acid batteries demand meticulous care to prevent sulfation – the crystallization of lead sulfate that permanently reduces capacity. A 2023 Golf Course Superintendents Association study found proper maintenance extends battery life by 38% on average.

| Maintenance Task | Frequency | Technical Specification |

|---|---|---|

| Water level check | Every 5 charges | Maintain 1/4″ above plates |

| Equalization charge | Monthly | 15.5V for 2-3 hours (48V system) |

| Terminal cleaning | Quarterly | Use brass brush and baking soda solution |

Lithium-Ion Performance Optimization

While maintenance-free, lithium batteries benefit from these practices:

- Partial charging: Keeping between 20-80% charge reduces stress on cells (except before storage)

- Temperature management: Avoid charging below 32°F (0°C) to prevent lithium plating

- Storage preparation: Store at 50% charge in climate-controlled environments

Common Mistakes and Professional Solutions

Overcharging lead-acid batteries accelerates water loss and plate corrosion. The solution: Use smart chargers with automatic voltage regulation and temperature compensation (like the Lester Summit II).

Deep discharging lithium batteries below 10% regularly can permanently damage cells. Install battery monitors (Victron BMV-712 recommended) that provide state-of-charge alerts.

Pinehurst Resort’s battery program demonstrates best practices – their fleet manager conducts monthly specific gravity tests on lead-acid batteries and uses cloud-connected monitors for lithium packs, achieving 7-year average lifespans versus the typical 4-5 years.

Charging System Selection and Installation Best Practices

The right charging system is crucial for battery safety and longevity, with different requirements for lead-acid versus lithium-ion chemistries. Professional installation following industry standards prevents hazards while optimizing performance.

Charger Selection Criteria

Matching charger specifications to battery chemistry prevents dangerous incompatibilities. Key parameters include:

- Voltage profile: Lead-acid requires 3-stage charging (bulk/absorption/float), while lithium needs constant-current constant-voltage (CCCV)

- Temperature compensation: Critical for lead-acid (adjusts voltage based on ambient temperature)

- Communication protocol: Lithium systems often require CAN bus or RS485 connectivity for BMS integration

Professional Installation Guidelines

Proper installation requires more than just plugging in a charger. Follow these steps for optimal results:

- Circuit sizing: Calculate wire gauge using the National Electric Code ampacity tables (typically 6 AWG for 48V systems)

- Grounding: Install separate equipment grounding conductor per NEC Article 250

- Ventilation planning: For lead-acid systems, ensure 1 CFM per square foot of floor space

- Surge protection: Install UL 1449 Type 2 SPDs on charging circuits

Troubleshooting Common Charging Issues

When facing charging problems, use this diagnostic approach:

| Symptom | Possible Cause | Professional Solution |

|---|---|---|

| Battery won’t hold charge | Sulfation (lead-acid) or cell imbalance (lithium) | Perform equalization charge or cell balancing |

| Charger shuts off prematurely | Thermal runaway protection triggered | Check battery temperature sensors and cooling |

The PGA Tour’s equipment managers use infrared thermography during charging to detect hot spots – a practice that caught several potential failures during the 2023 Players Championship. This level of proactive monitoring exemplifies industry best practices.

Lifecycle Analysis and Sustainable Battery Management

Understanding the complete lifecycle of golf cart batteries reveals critical opportunities for cost savings, safety improvements, and environmental responsibility. This comprehensive analysis covers from initial purchase through responsible disposal.

Total Cost of Ownership Comparison

| Cost Factor | Flooded Lead-Acid | AGM | Lithium-Ion |

|---|---|---|---|

| Initial Purchase | $800-$1,200 (48V set) | $1,200-$1,800 | $2,500-$4,000 |

| Expected Lifespan | 4-5 years | 5-6 years | 8-12 years |

| Maintenance Costs | $150/year (water, equalization) | $50/year | Negligible |

| Energy Efficiency | 70-75% | 80-85% | 95-98% |

Environmental Impact and Recycling

Proper end-of-life handling prevents ecological damage while recovering valuable materials:

- Lead-acid batteries: 99% recyclable – lead plates and polypropylene cases are reprocessed into new batteries

- Lithium batteries: Require specialized recycling – only 5% of lithium is currently recovered in the US

- Transport regulations: Both types are classified as hazardous materials during transport (DOT Class 8)

Emerging Technologies and Future Trends

The industry is evolving with several promising developments:

- Solid-state batteries (expected 2026-2028) promise 2x energy density with zero thermal runaway risk

- Battery-as-a-service models where golf courses lease rather than purchase battery systems

- AI-powered predictive maintenance using cloud-connected sensors to anticipate failures

Augusta National’s sustainability program sets an industry benchmark – their battery recycling initiative recovers 3.2 tons of lead annually, while their new lithium fleet reduced charging energy consumption by 37%. These practices demonstrate how forward-thinking facilities are addressing both economic and environmental concerns.

Advanced Monitoring and Smart Battery Management Systems

Modern battery monitoring solutions provide unprecedented insight into golf cart battery health, enabling proactive maintenance and preventing catastrophic failures. These systems have become essential for commercial operations and serious enthusiasts alike.

Real-Time Monitoring Technologies

Cutting-edge monitoring goes beyond simple voltage readings to provide comprehensive battery analytics:

- Individual cell monitoring (for lithium systems) tracks voltage differentials as small as 5mV to detect imbalances

- Internal resistance measurement identifies sulfation in lead-acid batteries before capacity loss becomes apparent

- Temperature profiling uses multiple sensors to detect hot spots indicating connection corrosion or cooling issues

Smart Charging Integration

Advanced systems automatically adjust charging parameters based on real-time conditions:

- Adaptive charging algorithms modify charge rates based on battery temperature and state-of-health

- Load balancing distributes charging current optimally across parallel battery banks

- Grid-responsive charging can shift charging times to off-peak periods when integrated with facility energy management

Implementation Case Study: Pebble Beach Golf Links

Their fleet management system demonstrates best practices:

| Component | Specification | Benefit |

|---|---|---|

| Cloud-connected BMS | 24/7 remote monitoring | Reduced downtime by 62% |

| Automated watering | Water Miser Pro systems | Cut maintenance hours by 75% |

| Predictive analytics | AI-based failure prediction | Extended average battery life to 6.3 years |

When implementing monitoring systems, always verify compatibility with your specific battery chemistry and charger specifications. Professional installation by certified technicians ensures proper sensor calibration and data accuracy – a critical factor often overlooked in DIY installations that leads to false readings.

Comprehensive Risk Management and Performance Validation

Implementing a complete battery safety and performance assurance program requires systematic approaches that address both immediate risks and long-term reliability. This final section synthesizes best practices from industrial and recreational applications.

Multi-Layer Risk Assessment Framework

Effective battery risk management requires addressing hazards at three levels:

| Risk Tier | Assessment Method | Mitigation Strategy |

|---|---|---|

| Chemical Hazards | pH testing (lead-acid), thermal imaging (lithium) | Spill containment systems, thermal barriers |

| Electrical Hazards | Insulation resistance testing, arc flash analysis | GFCI protection, insulated tool protocols |

| Mechanical Hazards | Vibration analysis, structural integrity checks | Anti-vibration mounts, corrosion-resistant hardware |

Performance Validation Protocol

Industry-standard validation procedures ensure batteries meet specifications throughout their lifecycle:

- Capacity testing: Conduct full discharge/charge cycles annually using calibrated loads

- Efficiency verification: Measure energy in vs energy out with precision meters (0.5% accuracy)

- Cycle life projection: Use accelerated aging tests (3x normal cycles) to predict remaining lifespan

Quality Assurance Implementation

The US Golf Association’s battery program demonstrates comprehensive QA:

- Documented procedures for all maintenance activities (ISO 9001 compliant)

- Calibration registry for all test equipment with NIST-traceable standards

- Failure analysis protocol including root cause determination and corrective actions

For optimal results, combine these technical measures with staff training programs certified by organizations like the Battery Council International. Their 40-hour technician certification covers the exact skills needed for proper golf cart battery management, reducing operational risks by up to 80% according to industry studies.

Conclusion

While golf cart batteries do not emit carbon monoxide, this comprehensive analysis reveals they require careful handling to address hydrogen gas risks (lead-acid), thermal runaway (lithium), and other safety considerations.

We’ve examined battery chemistries, charging protocols, monitoring systems, and lifecycle management – each presenting unique requirements for optimal performance and safety.

From proper ventilation to advanced BMS integration, these measures collectively ensure safe operation while maximizing battery lifespan.

Actionable Next Steps: Conduct a battery safety audit using the guidelines provided, invest in appropriate monitoring equipment for your battery type, and establish regular maintenance schedules.

By implementing these professional practices, you’ll protect both your equipment and personnel while achieving peak performance from your golf cart fleet.

Frequently Asked Questions About Golf Cart Battery Safety and Performance

Can golf cart batteries explode during charging?

While rare, lead-acid batteries can potentially explode if hydrogen gas accumulates in enclosed spaces and encounters an ignition source. Lithium batteries may experience thermal runaway if damaged or improperly charged.

Always charge in well-ventilated areas, keep terminals clean, and use manufacturer-approved chargers. The National Fire Protection Association recommends maintaining at least 3 feet of clearance around charging stations.

How often should I water my lead-acid golf cart batteries?

Check water levels every 5-10 charging cycles, adding distilled water when levels drop 1/4″ below the fill tube bottoms. Never add water before charging – the expanding electrolyte could overflow.

In hot climates, check more frequently as evaporation accelerates. Use a battery watering system like Flow-Rite to simplify maintenance and prevent overfilling.

Why does my golf cart battery die so quickly?

Premature failure typically stems from: sulfation (incomplete charging), improper water levels, loose connections, or excessive deep discharges.

A 48V battery pack showing more than 0.5V difference between batteries indicates imbalance. Perform monthly equalization charges and load tests to identify weak batteries before they affect the entire pack.

Is it worth upgrading from lead-acid to lithium batteries?

Lithium batteries offer 3-4x longer lifespan, 50% weight reduction, and near-zero maintenance, but cost 2-3x more initially.

For heavy-use applications (golf courses, resorts), the ROI typically occurs within 3-4 years through reduced replacement and labor costs. Light users may find lead-acid more economical despite shorter lifespan.

What’s the proper way to store golf cart batteries off-season?

For lead-acid: Clean terminals, fully charge, then disconnect. Store in cool (50-70°F), dry location and recharge monthly. Lithium batteries should be stored at 40-60% charge in climate-controlled spaces.

Never store depleted batteries – lead-acid will sulfate, lithium may enter protection mode. Professional storage facilities maintain optimal 40% humidity levels.

How can I tell if my golf cart batteries need replacement?

Key indicators include: inability to hold charge overnight, 30%+ reduced range, visible corrosion/swelling, or failing load tests. Use a digital hydrometer (lead-acid) – specific gravity below 1.225 after full charge signals deterioration.

Lithium batteries showing >20% capacity loss or voltage imbalance >0.3V between cells typically require replacement.

Are golf cart batteries dangerous to handle?

Lead-acid batteries contain sulfuric acid that can cause burns, while lithium batteries pose fire risks if damaged. Always wear acid-resistant gloves and eye protection when servicing.

Never stack batteries or place metal tools across terminals. The Battery Council International recommends OSHA-approved PPE including face shields for electrolyte handling.

Can I use automotive battery chargers for my golf cart?

Standard car chargers lack the multi-stage charging profiles golf cart batteries require. Using them can cause undercharging (sulfation) or overcharging (water loss).

Invest in a smart charger like the Lester Electrical Summit II that automatically adjusts for battery type (flooded/AGM/lithium) and includes temperature compensation for optimal charging.