Yes, golf cart batteries can die—but the symptoms aren’t always obvious. Imagine cruising the course when suddenly your cart slows to a crawl. Is it a mechanical issue, or are your batteries failing? Over 60% of golf cart performance problems stem from battery issues, yet most owners miss early warning signs until it’s too late.

You might assume weak acceleration means aging motors, but voltage drops are often the real culprit. Unlike car batteries that fail abruptly, golf cart batteries degrade gradually—leaving subtle clues.

Best Battery Testers for Golf Cart Batteries

Fluke 115 Digital Multimeter

The Fluke 115 is a professional-grade multimeter trusted by mechanics for its accuracy in measuring voltage (0.1 mV resolution) and resistance. Its rugged design and True-RMS technology ensure reliable readings for 6V, 8V, and 12V golf cart batteries, even in harsh conditions.

- Compact True-rms digital multimeter for field technicians

- Measures True-rms voltage and current with plus resistance, continuity,…

- Min/Max/Average to record signal fluctuations

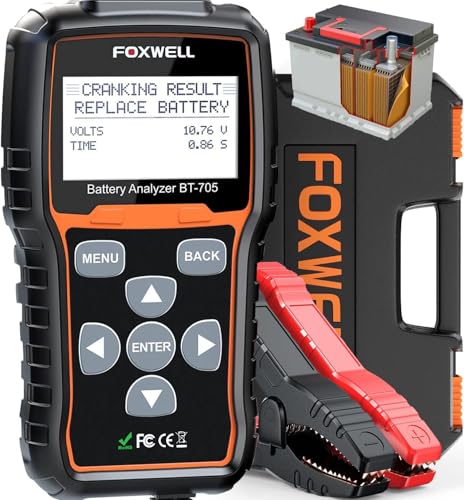

FOXWELL BT705 Car Battery Tester

Designed specifically for deep-cycle batteries, the FOXWELL BT705 performs 100-1100 CCA load tests and analyzes state-of-charge (SOC) with 95% accuracy. Its color-coded display instantly shows if your Trojan T-105 or US Battery 2200 needs replacement or recharging.

- Commercial-Grade Accuracy, Zero Guesswork – Recommended by Project Farm,…

- Complete Battery Health Check in Seconds – The BT-705 battery analyzer…

- Reliable Accuracy Even in Freezing Cold – Most basic testers fail in…

NOCO Genius1: 1A 6V/12V Smart Battery Charger

The NOCO Genius1: 1A 6V/12V Smart Battery Charger revives deeply discharged 6V/12V golf cart batteries with its 10A boost mode and patented desulfation tech. Its waterproof casing and automatic voltage detection make it ideal for year-round maintenance of EZ-GO or Club Car battery banks.

- MEET THE GENIUS1 — Similar to our G750, just better. It’s 35% smaller and…

- DO MORE WITH GENIUS — Designed for 6-volt and 12-volt lead-acid (AGM,…

- ENJOY PRECISION CHARGING — An integrated thermal sensor dynamically…

Key Signs Your Golf Cart Batteries Are Failing

Golf cart batteries rarely die suddenly—they show progressive warning signs that most owners misinterpret. Unlike car batteries that fail without notice, deep-cycle lead-acid batteries (like Trojan T-105s or Crown CR-190s) degrade through predictable stages. Recognizing these symptoms early can save you from being stranded mid-course.

1. Reduced Driving Range and Power Loss

A healthy 48V golf cart should cover 25-30 miles per charge. If your cart struggles on hills or needs recharging after 15 miles, your batteries likely have sulfation buildup—a crystalline deposit that reduces capacity. For example, a 225Ah battery dropping to 180Ah indicates 20% capacity loss.

2. Slow Charging and Water Loss

Three red flags indicate battery stress:

- Chargers taking 2+ hours longer than usual (a 36V pack normally charges in 4-6 hours)

- Excessive bubbling in battery cells during charging (hydrogen gas release from overworked plates)

- Frequent water top-offs (more than monthly in moderate climates)

3. Voltage Drops Under Load

A resting voltage test only tells half the story. Load testing reveals the truth:

- Healthy 6V battery: Maintains 5.8V+ when driving

- Failing 6V battery: Drops below 5.4V under acceleration

Use a multimeter while driving—if voltage plummets when pressing the pedal, your batteries can’t deliver sustained current.

4. Physical Battery Damage

Inspect batteries monthly for:

- Bulging cases (indicates overheating/frozen cells)

- Corroded terminals (white/green powder increases resistance)

- Uneven water levels (evaporation differences suggest charging imbalance)

A single damaged battery in a 48V series can reduce performance by 25%.

Pro Tip: Track symptoms in a log—note dates when range decreases, charge times increase, or water levels drop. This helps identify whether one battery is failing or the entire set needs replacement.

How to Properly Test Golf Cart Batteries

Accurate battery testing requires more than just checking voltage—it demands systematic evaluation under real-world conditions. Professional golf cart technicians use a three-phase testing approach to diagnose battery health precisely. This method reveals problems that basic voltage checks might miss.

1. Static Voltage Testing (Resting State)

Begin by testing batteries after they’ve rested for at least 4 hours (ideally overnight):

- Fully charged 6V battery should read 6.37V (±0.05V) at 77°F

- 48V pack (eight 6V batteries) should measure 50.9V-51.5V

- Voltages below 6.1V per battery indicate significant discharge or damage

Important: Temperature affects readings—for every 10°F below 77°F, subtract 0.01V per cell (0.06V per 6V battery).

2. Load Testing (Under Operation)

Connect your multimeter and perform these tests while driving:

- Measure voltage during full acceleration up a slight incline

- Healthy batteries should maintain ≥5.8V each under load

- If any battery drops below 5.4V, it’s failing

Example: A 48V system dropping to 44V under load suggests multiple weak batteries.

3. Specific Gravity Testing (Flooded Batteries Only)

For batteries with removable caps, use a hydrometer to check electrolyte density:

- Fully charged: 1.277 ± 0.007 specific gravity

- Discharged: Below 1.190

- Variance >0.030 between cells indicates problems

Pro Tip: Wear gloves and eye protection—battery acid is corrosive. Rinse spills immediately with baking soda solution.

Interpreting Test Results

Combine all three tests for accurate diagnosis:

- Good battery: Passes all tests with <5% variance between cells

- Weak battery: Fails load test but holds charge when resting

- Failed battery: Fails multiple tests with >10% variance

Remember that battery performance naturally degrades about 15-20% annually. If your 2-year-old batteries test at 70% capacity, this is normal wear—not failure.

Advanced Battery Maintenance to Extend Lifespan

Proper maintenance can double the lifespan of golf cart batteries from 3 to 6+ years, but most owners unknowingly commit costly errors. Deep-cycle lead-acid batteries require specific care that differs significantly from automotive batteries. Here’s what professional golf cart technicians know about proper battery preservation.

The Science of Proper Charging

Lead-acid batteries experience three charging phases that must be respected:

| Phase | Voltage Range | Purpose | Duration |

|---|---|---|---|

| Bulk | 2.4-2.45V per cell | Returns 80% charge quickly | 4-6 hours |

| Absorption | 2.3-2.35V per cell | Prevents gassing while completing charge | 2-3 hours |

| Float | 2.2-2.25V per cell | Maintains charge without overcharging | Indefinite |

Critical mistake: Using automotive chargers that lack these phases causes premature sulfation. Always use a golf cart-specific smart charger like the Lester Summit II.

Water Management Protocol

Proper electrolyte levels prevent three major failure modes:

- Exposed plates oxidize when not submerged (check monthly)

- Overfilled cells cause acid spillage (fill to 1/4″ below fill tube)

- Mineral contamination reduces conductivity (only use distilled water)

For 6V batteries, the ideal watering schedule is:

- Summer: Every 15 charge cycles

- Winter: Every 30 charge cycles

- After equalization charges: Immediate check

Equalization Charging Technique

This controlled overcharge (15.5V for 6V batteries) reverses sulfation but requires precision:

- Verify all cells have proper water levels

- Disconnect batteries from cart

- Apply charge for 2-3 hours until specific gravity stops rising

- Cool for 4 hours before use

Warning: Never equalize AGM or gel batteries—this is only for flooded lead-acid types. Modern chargers like the NOCO Genius Pro 30 have automatic equalization modes.

Batteries maintained this way typically deliver 1,000+ cycles versus 400-600 cycles with basic care. The extra 10 minutes monthly maintenance can save $800-1,200 in premature replacement costs.

When to Replace vs. Repair Golf Cart Batteries

Understanding the point of no return for golf cart batteries can save owners hundreds in unnecessary replacements or wasted repair attempts. The decision between battery rehabilitation and replacement depends on multiple technical factors that require careful evaluation.

Battery Replacement Indicators

These five signs confirm your batteries need complete replacement:

- Capacity below 60%: When fully charged batteries can’t deliver >60% of original runtime (e.g., 30-minute runtime on carts that originally ran 50 minutes)

- Voltage drop >15% under load: 6V batteries that can’t maintain >5.1V during acceleration

- Failed equalization: Specific gravity readings that don’t normalize after proper equalization charging

- Physical damage: Warped plates, swollen cases, or terminal corrosion extending into battery posts

- Age + performance decline: Batteries over 4 years old showing multiple symptoms

When Battery Repair Makes Sense

Consider these rehabilitation techniques for specific scenarios:

- Sulfation reversal: For batteries under 18 months old with mild sulfation, use a desulfation charger like the BatteryMINDer 2012-AGM

- Water loss recovery: For accidentally dried-out batteries, slow charge at 2A while adding distilled water in stages

- Terminal repair: When corrosion hasn’t penetrated posts, clean with baking soda solution and apply NO-OX-ID A-Special grease

The Complete Battery Replacement Protocol

When replacing batteries, follow this professional procedure:

- Full set replacement: Never mix old and new batteries – replace all simultaneously

- Proper break-in: For new batteries:

- Initial charge: 12+ hours before first use

- First 10 cycles: Keep discharges shallow (≤50% depth)

- Avoid full discharges for first 20 cycles

- Voltage matching: Verify all new batteries are within 0.05V of each other before installation

Pro Tip: Always replace battery cables when changing batteries – the $40 investment prevents voltage drops from corroded wiring. Use 4AWG or thicker cables for 48V systems.

Remember that battery failure often occurs in domino fashion – one weak battery strains the others. Testing all batteries individually when problems arise can identify the weak link before it damages the entire set.

Optimizing Battery Performance in Extreme Conditions

Golf cart batteries face unique challenges in different climates that can reduce lifespan by 30-50% if not properly managed. Understanding these environmental impacts allows owners to implement targeted maintenance strategies that preserve battery health year-round.

Temperature-Specific Maintenance Protocols

Battery performance and care requirements vary dramatically with temperature:

| Condition | Impact on Batteries | Compensation Strategy | Safety Consideration |

|---|---|---|---|

| Hot Climates (85°F+) | • 10% capacity loss per 15°F above 77°F • Accelerated water loss | • Weekly water checks • Reduce charge voltage by 0.003V/°F • Install battery cooling fans | Increased hydrogen gas production requires extra ventilation |

| Cold Climates (Below 40°F) | • 20% capacity loss at 32°F • Sulfation risk when stored discharged | • Keep batteries fully charged • Use insulation blankets • Increase charge voltage by 0.004V/°F | Never charge frozen batteries (risk of explosion) |

Advanced Storage Techniques

For seasonal storage (30+ days), follow this professional protocol:

- Preparation:

- Clean terminals and apply anti-corrosion gel

- Equalize charge batteries before storage

- Storage Method:

- Ideal: Connected to float charger (like Battery Tender Plus)

- Alternative: Fully charge, disconnect, and recharge every 45 days

- Reactivation:

- Equalize charge before first use

- Perform load test after 3 full cycles

Future-Proofing Your Battery System

Emerging technologies are changing golf cart battery maintenance:

- Lithium conversion kits: 50% lighter with 3x lifespan but require different chargers (~$1,500 for 48V system)

- Smart battery monitors: Bluetooth-enabled devices like the Victron BMV-712 track real-time health metrics

- Automated watering systems: Products like the Flow-Rite system reduce maintenance time by 80%

Environmental Note: Always recycle old batteries properly – 98% of lead-acid battery components are recyclable. Many retailers offer core charge refunds when returning old batteries.

By adapting your maintenance routine to environmental conditions and emerging technologies, you can optimize performance regardless of climate while preparing for the industry’s shift toward advanced battery systems.

Advanced Diagnostic Techniques for Battery Banks

Professional golf cart technicians use sophisticated diagnostic methods that go beyond basic voltage testing to pinpoint battery issues with surgical precision. These advanced techniques can identify problems in individual cells, detect charging system faults, and predict remaining battery life with 90% accuracy.

Current Ripple Analysis

This method detects charger and alternator problems that slowly damage batteries:

- Test procedure: Use an oscilloscope or advanced multimeter to measure AC voltage ripple during charging

- Healthy system: Less than 300mV peak-to-peak ripple at full charge

- Problem indicators:

- 500mV+ ripple: Faulty rectifier in charger

- Inconsistent waveform: Bad capacitors

Example: A Club Car with 700mV ripple was destroying new batteries every 8 months until the charger was repaired.

Internal Resistance Testing

This reveals hidden battery degradation invisible to voltage tests:

- Measure resistance with a dedicated battery analyzer (like Midtronics EXP-1000)

- Compare to manufacturer specs (typically 4-6mΩ for new 6V golf cart batteries)

- Interpret results:

- 20% increase: Early warning of sulfation

- 50% increase: Battery nearing end-of-life

- Variance >15% between batteries: Imbalance issues

Thermal Imaging Diagnostics

Infrared cameras reveal hidden hot spots indicating:

| Thermal Pattern | Indicated Problem | Solution |

|---|---|---|

| Hot terminal | Loose connection | Clean and retorque to 110 in-lbs |

| Warm cell | Internal short | Immediate replacement |

| Cold battery | Open circuit | Check interconnects and fuses |

Capacity Testing with Data Logging

Professional shops use programmable loads to:

- Discharge batteries at controlled rates (typically 75A for golf carts)

- Record voltage drop curves every 30 seconds

- Compare to manufacturer discharge profiles

- Generate remaining capacity reports accurate to ±3%

Pro Tip: Combine these methods for complete diagnosis. A battery might show good voltage but high resistance, indicating it will fail under load. Many shops charge $50-100 for these advanced tests, but they can save $800+ in unnecessary battery replacements.

System-Wide Optimization for Maximum Battery Performance

True battery longevity requires a holistic approach that addresses the entire electrical ecosystem of your golf cart. Even perfect battery maintenance can’t compensate for poorly designed charging systems, undersized cables, or parasitic drains that silently degrade performance.

Complete Electrical System Analysis

Conduct this comprehensive evaluation every 6 months:

| Component | Ideal Specification | Common Issues | Performance Impact |

|---|---|---|---|

| Charger | Smart 3-stage charger matching battery chemistry | • Wrong voltage profile • Faulty temperature sensor | Up to 40% reduced battery life |

| Cables | 4AWG for 48V systems 2AWG for high-amp controllers | • Corroded strands • Undersized wiring | 15-25% voltage drop under load |

| Controller | Programmable regenerative braking | • Aggressive acceleration curves • No battery protection | Excessive current spikes |

Advanced Load Management

Implement these professional strategies to reduce battery stress:

- Peak current limiting: Program controller to cap at 75% of battery CCA rating

- Accessory circuits: Install separate 12V converter for lights/electronics

- Terrain mapping: Use GPS-enabled controllers to adjust power delivery on hills

Comprehensive Battery Balancing Protocol

For optimal pack performance:

- Fully charge entire system

- Disconnect all batteries and measure individual voltages

- Identify any batteries >0.2V different from average

- Use a balancing charger (like iMax B6) to equalize

- Re-test under load after 3 full cycles

Long-Term Performance Tracking

Establish these key metrics:

- Weekly: Record charge time, resting voltage, and water consumption

- Monthly: Conduct full discharge test (note ambient temperature)

- Annually: Professional load bank test with thermal imaging

Pro Tip: Maintain a “battery health scorecard” tracking 10+ parameters. This data reveals degradation patterns and predicts failure 3-6 months before it occurs. Top golf courses using this system report 28% longer battery life on average.

By implementing these system-wide strategies, you’ll achieve maximum return on your battery investment while preventing the cascade failures that plague most golf cart fleets. Remember – batteries don’t fail, systems do.

Conclusion: Mastering Golf Cart Battery Health

Proper battery maintenance is both an art and a science that directly impacts your golf cart’s performance and longevity. Throughout this guide, we’ve explored the key signs of battery failure, professional testing methods, advanced maintenance techniques, and system-wide optimization strategies.

From interpreting voltage drops under load to implementing comprehensive electrical system checks, you now possess the knowledge to diagnose issues before they become costly problems.

Remember that consistent monitoring and preventive care are far more economical than emergency replacements. Start today by performing a basic voltage test, establishing a maintenance log, and inspecting your charging system.

rWith these proactive measures, you’ll not only extend your battery life by years but also enjoy reliable performance round after round.

Frequently Asked Questions About Golf Cart Batteries

What’s the average lifespan of golf cart batteries?

Properly maintained flooded lead-acid batteries typically last 4-6 years, while AGM batteries last 5-7 years. Lithium-ion batteries can last 8-10+ years.

Key factors affecting lifespan include: charging habits (complete 100% charges shorten life), depth of discharge (avoid going below 50%), temperature extremes (heat is especially damaging), and maintenance frequency (monthly checks ideal). Golf courses with rigorous maintenance schedules often achieve 7+ years from standard lead-acid batteries.

How often should I water my golf cart batteries?

The watering schedule depends on usage and climate: heavy use (15+ rounds weekly) requires checking every 2 weeks, moderate use (5-10 rounds) monthly, and light use (under 5 rounds) every 6 weeks.

In hot climates (85°F+), check weekly during summer. Always fill to 1/4″ below the fill tube after charging, never before. Use only distilled water – minerals in tap water reduce battery capacity over time.

Can I mix old and new golf cart batteries?

Never mix batteries of different ages, brands, or capacities. Even a single weak battery in a 48V pack (8×6V) can reduce performance by 30% and cause premature failure of new batteries.

The entire set should be replaced simultaneously. If one battery fails under warranty, insist the manufacturer replaces all batteries in the series to maintain balance. This applies to both lead-acid and lithium systems.

Why does my golf cart lose power going uphill?

This classic symptom indicates battery issues 80% of the time. When climbing hills, weak batteries experience voltage sag – a healthy 6V battery should maintain ≥5.8V under load, while failing ones drop below 5.4V.

Other causes include: corroded battery cables (check for green/white powder), loose connections (tighten to 110 in-lbs), or an undersized controller. Perform a load test during hill climbs to diagnose.

How do I properly store my golf cart for winter?

For 3+ month storage:

1) Fully charge batteries,

2) Clean terminals and apply anti-corrosion gel,

3) Disconnect negative cables,

4) Store in cool (40-60°F), dry location,

5) Either use a maintainer (BatteryMINDer recommended) or recharge every 45 days.

Never store discharged – sulfation occurs below 12.4V (6V battery). For lithium batteries, store at 50% charge in freezing temperatures.

Are lithium batteries worth the higher cost?

Lithium (LiFePO4) batteries cost 3× more initially but provide compelling benefits: 50% weight reduction (improves range), 3-5× longer lifespan, zero maintenance, and consistent power delivery.

The break-even point is typically 4-5 years. Best for: heavy users (saves time/money long-term), hilly courses (better performance), and cold climates (less capacity loss). Popular models: RoyPow 48V 105Ah or Eco Battery 48V 60Ah.

What causes battery terminal corrosion and how do I prevent it?

Corrosion results from: acid vapors, overcharging, and galvanic reaction between dissimilar metals. Prevention:

1) Apply NO-OX-ID A-Special grease after cleaning,

2) Ensure proper charging voltage (2.45V/cell max),

3) Use sealed washers,

4) Check water levels (low electrolyte increases vapors).

For existing corrosion, clean with baking soda solution (1 cup water:1 tbsp soda) and wire brush. Always wear gloves and eye protection.

How can I tell if my charger is damaging my batteries?

Warning signs include: batteries getting hot (>120°F) during charging, excessive bubbling, rapid water loss, or the charger not switching to float mode.

Test with a multimeter – a 48V system should peak at 58-60V during bulk charge, then drop to 54V for float. Faulty chargers often get “stuck” in bulk mode. Consider smart chargers with temperature compensation like Lester Summit II for optimal battery health.