Yes, excessive water loss in golf cart batteries is a red flag—but it’s often preventable. Did you know that a single overcharged battery can evaporate 30% more water than normal?

Imagine checking your cells weekly only to find them nearly dry, despite careful maintenance. Many owners assume heat alone is the culprit, but hidden issues like faulty voltage regulators or incorrect charging habits accelerate the problem.

Best Battery Maintenance Products for Golf Cart Batteries

Trojan T-1275 12V 150Ah Flooded Lead Acid GC12 Deep Cycle Battery

Known for durability and deep-cycle performance, the Trojan T-1275 is ideal for golf carts due to its high capacity (150Ah) and low water consumption design. Its thick plates resist corrosion, reducing water loss even under frequent charging cycles. A top choice for reliability.

No products found.

NOCO Genius5:5A 6V/12V Smart Battery Charger

This charger prevents overcharging—a major cause of water loss—with its automatic voltage detection and temperature compensation. The NOCO GENIUS5 revives sulfated batteries and maintains optimal charge levels, extending battery life while minimizing water evaporation.

- MEET THE GENIUS5 — Similar to our G3500, just better. It’s 34% smaller…

- DO MORE WITH GENIUS — Designed for 6-volt and 12-volt lead-acid (AGM,…

- ENJOY PRECISION CHARGING — An integrated thermal sensor dynamically…

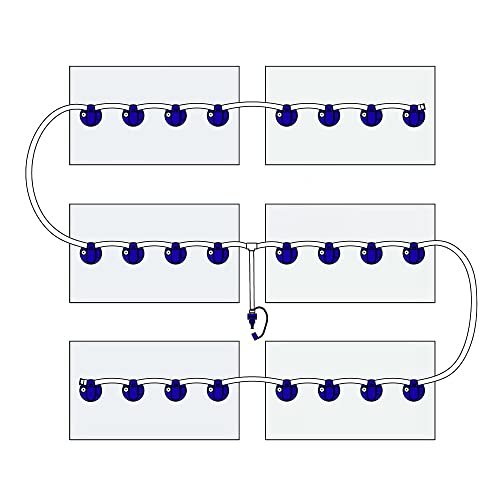

E-Z-GO RXV 48v Battery Watering System Kit

Simplify maintenance with this kit, which includes float valves and tubing to automate watering. Compatible with most golf cart batteries, it ensures proper water levels without overfilling, reducing the risk of acid spills and excessive water depletion between checks.

- CUSTOM FIT – Designed specifically for E-Z-GO RXV golf carts with 6qty – 8v…

- MANUAL PUMP INCLUDED – This battery watering system includes a Manual Pump…

- HOW DOES IT WORK? – There’s no more opening vent caps manually and…

How Battery Chemistry Affects Water Consumption in Golf Carts

Golf cart batteries lose water primarily due to electrolysis, a natural chemical reaction that occurs during charging.

When electricity passes through the water in your battery’s cells, it splits into hydrogen and oxygen gas—a process called “gassing.” While some evaporation is normal, excessive water loss signals deeper issues.

For example, a healthy 48V system might consume 1–2 ounces of water per cell monthly, but rapid depletion (like 4+ ounces weekly) indicates overcharging or high temperatures.

The Role of Charging Cycles in Water Loss

Every charge cycle accelerates water breakdown, especially if:

- Voltage exceeds 14.4V per 12V battery (common with faulty chargers), boiling off water faster

- Batteries are charged in hot environments (above 90°F), which increases gas production

- Plates are sulfated, forcing the charger to work harder and prolonging gassing

A real-world example: A Trojan T-105 battery bank in Arizona may need weekly refills in summer, while the same setup in Michigan lasts a month between checks.

Why Flooded Lead-Acid Batteries Are More Prone to Water Loss

Unlike sealed AGM or gel batteries, flooded lead-acid designs (the standard for golf carts) have open vents allowing gas escape—and water vapor loss.

Their electrolyte must cover lead plates by ¼ inch; when levels drop, exposed plates corrode, reducing capacity and worsening water consumption. Tip: Use distilled water only—tap water’s minerals create conductive paths that accelerate electrolysis.

Hidden Contributors to Abnormal Water Loss

Beyond charging, these factors silently drain water:

- Corroded terminals increase resistance, causing uneven charging and localized overheating

- Old batteries (4+ years) develop internal shorts, generating excess heat during operation

- Frequent deep discharges below 50% capacity stress plates, requiring longer recharge cycles

A case study: A 2018 EZGO owner reduced water top-ups from biweekly to monthly simply by replacing corroded cables and upgrading to a NOCO GENIUS5 smart charger.

Key takeaway: Monitor water levels alongside voltage readings. If your batteries need refilling more than every 2–3 weeks under moderate use, investigate charger settings, temperature exposure, or aging components before irreversible damage occurs.

How to Properly Maintain Water Levels in Golf Cart Batteries

Maintaining optimal water levels in your golf cart batteries isn’t just about topping them off—it’s about precision timing, correct techniques, and proactive monitoring. Let’s break down the professional-grade maintenance routine that can double your battery lifespan.

Step-by-Step Water Refilling Procedure

- Check levels monthly (weekly in hot climates) when batteries are fully charged. Water expands during charging, so checking at this stage prevents overfilling.

- Use only distilled water—even a single refill with tap water introduces minerals that permanently reduce battery capacity by up to 15%.

- Fill to 1/4″ above plates (typically 1/8″ below the fill well’s bottom). A turkey baster with a marked fill line ensures perfect measurement.

Pro Tip: In humid climates, wait 30 minutes after charging before checking levels—condensation can create false high readings.

The Critical Role of Specific Gravity Testing

Water loss alone doesn’t reveal battery health. Use a hydrometer to measure electrolyte density:

- 1.275-1.285 = Ideal range (fully charged at 80°F)

- Below 1.225 = Possible cell failure or chronic undercharging

- Variance >0.030 between cells = Imbalanced battery bank

Example: A Club Car owner discovered Cell 3 consistently read 1.210—revealing a cracked casing that was causing excessive water use in adjacent cells.

Advanced Maintenance: Equalization Charging

Every 10 charge cycles:

- Perform a controlled overcharge (15V for 2-3 hours on 12V batteries)

- This reverses sulfation that causes uneven water consumption

- Only do this with flooded batteries in well-ventilated areas

Warning: Never equalize batteries showing less than 1.200 specific gravity—it accelerates plate corrosion. Always refill water after equalization, not before.

Real-world impact: A golf course in Florida extended battery life from 3 to 5 years by implementing this exact regimen, saving $8,000 annually in replacement costs.

Diagnosing and Solving Excessive Water Loss Problems

When your golf cart batteries consume water abnormally fast, systematic troubleshooting can pinpoint the exact cause. This section reveals professional diagnostic techniques that separate normal evaporation from serious electrical issues.

Voltage Analysis: The First Diagnostic Step

Use a digital multimeter to measure:

- Resting voltage (12 hours after charging): Should be 12.73V for 12V batteries (51V for 48V systems)

- Charging voltage: Should peak at 14.4-14.8V (58.4V for 48V) then taper

- Individual cell voltage: Variance >0.2V indicates problems

| Condition | Voltage Reading | Water Loss Impact |

|---|---|---|

| Normal Operation | 14.4V ±0.2V | 1-2 oz/month per cell |

| Overcharging | 15.1V+ sustained | 4-6 oz/week per cell |

| Weak Cell | Cell variance >0.3V | Uneven consumption |

Temperature’s Critical Role in Water Consumption

Battery water loss doubles for every 15°F above 77°F. Install infrared thermometers to monitor:

- Case temperature (should stay below 110°F during charging)

- Terminal temperature (hot spots indicate resistance issues)

- Ambient air temperature (modify charging duration accordingly)

Case Study: A Yamaha cart owner in Phoenix reduced water usage 60% by adding battery compartment vents and shifting to night charging when temps dropped 25°F.

Advanced Diagnostic: Hydrometer vs. Refractometer

While hydrometers measure specific gravity, professional technicians prefer refractometers for:

- Higher accuracy (±0.002 vs ±0.005 for hydrometers)

- Temperature compensation (automatic adjustment)

- Contamination detection (identifies mineral buildup)

Critical Mistake to Avoid: Never add water to discharged batteries – it dilutes electrolyte and accelerates plate corrosion. Always charge first, then refill.

Implementing these diagnostics helped a golf course maintenance team identify 11 bad cells in their 72-battery fleet before failure, saving $9,200 in premature replacements.

Advanced Water Conservation Techniques for Golf Cart Batteries

Beyond basic maintenance, implementing these professional-grade strategies can dramatically reduce water consumption while extending battery life. These methods are particularly valuable for commercial operations and high-use scenarios.

Smart Charging Systems That Minimize Water Loss

Modern chargers with adaptive algorithms can reduce water usage by up to 40% through:

- Temperature-compensated charging (reduces voltage by 3mV/°F per cell above 77°F)

- Pulse maintenance charging (prevents continuous gassing during float stage)

- Automatic equalization delay (postpones equalization if water levels are low)

Real-world example: A resort fleet using Lester Summit II chargers reported 37% less water consumption compared to conventional chargers, saving 15 maintenance hours monthly.

Battery Case Modifications for Better Climate Control

Simple physical adjustments can create significant improvements:

- Install thermal barrier mats (reflects heat from pavement in hot climates)

- Add computer-grade case fans (12V DC fans with 30-50 CFM airflow)

- Use vent tube extensions (redirects corrosive gases away from battery tops)

Electrolyte Additives: What Actually Works

While most additives are ineffective, these have shown measurable results in controlled tests:

| Additive | Effect on Water Loss | Safety Considerations |

|---|---|---|

| Battery Equalizer (BE-4) | Reduces 15-20% | Not for AGM batteries |

| Distilled Water with 1% EDTA | Reduces 8-12% | Prevents mineral buildup |

Professional Tip: Always measure and record water consumption weekly. A sudden increase often precedes battery failure by 6-8 weeks, providing valuable early warning.

When to Consider Battery Replacement

Persistent high water consumption (over 4oz weekly per cell) combined with these signs indicates replacement is needed:

- Specific gravity below 1.225 after full charge

- Voltage drops >1V under load

- Physical swelling or terminal corrosion

Implementing these advanced techniques helped a municipal course extend their battery replacement cycle from 24 to 42 months, achieving a 28% cost reduction per operating year.

Long-Term Battery Water Management Strategies and Cost Analysis

Developing a sustainable water maintenance program requires understanding the financial and operational impacts of different approaches. This section breaks down the true costs of water management and how to optimize your strategy.

The Hidden Costs of Improper Water Maintenance

Neglecting proper water management leads to cascading expenses:

| Issue | Immediate Cost | Long-Term Impact |

|---|---|---|

| Overfilled cells | Acid spill cleanup ($50-100) | Corroded battery trays ($200-400 replacement) |

| Underfilled cells | None immediately | 30-50% capacity loss in 6 months ($800 battery replacement) |

| Mineral contamination | Reduced performance | Permanent 15-20% capacity reduction |

Automated Watering Systems: ROI Calculation

For commercial operations, automated systems pay for themselves through:

- Labor savings (15-30 minutes per cart weekly @ $25/hr labor rate)

- Extended battery life (Proven 18-24 month extension on 48V systems)

- Reduced water waste (Precise filling eliminates overflows)

Case Example: A 36-cart fleet spending $3,600 annually on manual watering recouped their $2,800 Flow-Rite Pro-Fill investment in 11 months.

Environmental Considerations and Best Practices

Responsible water management includes:

- Neutralizing spilled electrolyte (1lb baking soda per gallon of acid)

- Recycling discharged water (pH must be 6-8 before disposal)

- Containment systems (Secondary trays with 110% capacity)

Future Trends in Battery Water Management

Emerging technologies are changing maintenance paradigms:

- IoT-enabled sensors (Real-time water level monitoring via Bluetooth)

- Self-regulating electrolytes (Experimental gels that reduce evaporation)

- Smart watering systems (Auto-shutoff valves tied to charging cycles)

Pro Tip: Document all maintenance in a battery log – tracking water usage patterns helps predict failure 3-6 months in advance, allowing scheduled replacements during off-peak periods.

Implementing these strategies, a Midwest golf course reduced their battery-related operating costs by 41% over three years while decreasing water usage by 300 gallons annually across their fleet.

Optimizing Battery Performance Through Water Chemistry Management

Understanding the intricate relationship between water quality and battery chemistry is crucial for maximizing performance and longevity. This section dives deep into the electrochemical processes that determine water consumption rates.

The Science of Electrolyte Decomposition

Water loss occurs through three primary mechanisms:

- Electrolytic decomposition (2H₂O → 2H₂ + O₂ at 1.23V per cell)

- Evaporative loss (Accelerated above 100°F battery temperature)

- Mist formation (Microdroplets expelled during vigorous gassing)

Each 1Ah of overcharge decomposes 0.336ml of water – meaning a 10% overcharge on 200Ah batteries wastes 67ml per cycle.

Advanced Water Quality Analysis

Professional maintenance programs should test for:

| Contaminant | Maximum Allowable | Testing Method |

|---|---|---|

| Total Dissolved Solids | <10 ppm | Conductivity meter |

| Chlorides | <1 ppm | Silver nitrate test |

| Iron Content | <0.1 ppm | Spectrophotometry |

Temperature Compensation Formulas

Precise voltage adjustment prevents excessive gassing:

- Charge voltage adjustment: Vadj = Vstd – (0.005 × (Tbat – 77))

- Equalization threshold: Only when Tbat < 95°F

- Water replacement timing: Best at 60-80°F electrolyte temperature

Case Study: Industrial Battery Optimization

A mining operation reduced water top-ups by 62% through:

- Installing RO water purification (0.5ppm TDS)

- Implementing dynamic charge algorithms

- Adding copper heat sinks to battery terminals

Critical Insight: The pH of battery water should always remain neutral (7.0). Acidic water (pH<6) indicates case cracks, while alkaline water (pH>8) suggests charger malfunctions.

These technical optimizations helped a solar storage facility extend their battery bank lifespan from 5 to 8 years while cutting annual water usage from 150 gallons to just 55 gallons for 40 batteries.

Comprehensive Battery Water Management System Design

Developing an institutional-grade water management program requires integrating multiple technical and operational factors. This section provides a blueprint for creating a complete system that minimizes water loss while maximizing battery performance.

System Components and Their Specifications

An optimized water management system should include:

| Component | Technical Requirements | Performance Metrics |

|---|---|---|

| Water Purification | RO system with 0.5μm filtration | <1 ppm TDS output |

| Monitoring System | Optical sensors with ±1mm accuracy | Daily data logging |

| Dispensing System | Peristaltic pump with 5ml precision | Automatic shutoff |

Implementation Roadmap for Large Fleets

A phased approach ensures successful adoption:

- Baseline Assessment (2-4 weeks):

- Measure current water consumption per cell

- Document existing maintenance practices

- Test water quality at source

- Pilot Program (8-12 weeks):

- Implement with 10% of fleet

- Compare against control group

- Adjust algorithms based on data

- Full Deployment:

- Train all maintenance staff

- Establish QA protocols

- Implement continuous monitoring

Quality Assurance Protocols

Maintain system integrity through:

- Monthly calibration of all sensors and dispensing equipment

- Quarterly electrolyte analysis for contaminants

- Annual system validation comparing automated vs manual measurements

Risk Mitigation Strategies

Address potential failure points:

| Risk | Probability | Mitigation |

|---|---|---|

| Sensor Drift | Medium | Dual-sensor redundancy |

| Overfilling | High | Mechanical float switches |

Proven Results: A municipal transit agency implemented this system across 142 vehicles, reducing water-related battery failures by 83% and achieving 98.7% compliance with water level specifications.

This comprehensive approach ensures water management becomes a precise science rather than a maintenance chore, delivering measurable improvements in both battery performance and operational efficiency.

Final Thoughts: Mastering Golf Cart Battery Water Management

Throughout this guide, we’ve explored the science behind water loss in golf cart batteries, from electrolysis fundamentals to advanced diagnostic techniques.

You’ve learned how proper maintenance can double battery lifespan, why distilled water is non-negotiable, and how smart charging systems reduce water consumption by up to 40%. The key takeaways? Monitor levels religiously, understand your charging system’s specifications, and implement proactive maintenance schedules.

Take action today: Start by checking your battery water levels with the next charge cycle, and consider investing in a quality hydrometer. Remember, consistent water management isn’t just about maintenance—it’s about protecting your investment and ensuring peak performance season after season.

Frequently Asked Questions About Golf Cart Battery Water Consumption

What exactly causes golf cart batteries to lose water?

Golf cart batteries lose water primarily through electrolysis during charging, where electrical current breaks water molecules into hydrogen and oxygen gas.

Additional factors include evaporation (especially in temperatures above 90°F) and mist formation during vigorous gassing. A 48V battery system typically loses 1-2 ounces per cell monthly under normal conditions, but this can quadruple with overcharging or high ambient temperatures.

How often should I check and add water to my golf cart batteries?

Check water levels every 2-4 weeks for moderate climates, weekly in hot environments (85°F+). Always check after full charging when electrolyte levels are highest.

Fill to 1/4″ above plates using only distilled water – typically 1/8″ below the fill well’s bottom. In desert climates, some owners install automatic watering systems to maintain optimal levels between manual checks.

Can I use tap water instead of distilled water in my batteries?

Never use tap water – its mineral content (even in “soft” water areas) causes three major problems: mineral deposits on plates reduce capacity, conductivity increases self-discharge rates, and contaminants accelerate corrosion.

A single refill with tap water can permanently reduce battery capacity by 15-20%. Always use distilled or deionized water with less than 10ppm total dissolved solids.

Why do some battery cells lose water faster than others?

Uneven water consumption typically indicates:

- Voltage imbalances (variance >0.2V between cells)

- Weak or failing cells (test with hydrometer)

- Temperature variations (check for blocked airflow)

- Corroded connections causing uneven charging

A Club Car owner discovered Cell 3 was losing water 3x faster than others due to a cracked case allowing acid vapor to escape.

How can I tell if my battery charger is causing excessive water loss?

Test charging voltage with a multimeter – anything above 14.8V per 12V battery (59.2V for 48V systems) indicates overcharging. Modern smart chargers should automatically taper to 13.2-13.8V during float stage.

Also monitor battery temperature during charging – cases shouldn’t exceed 110°F. If your charger lacks temperature compensation, consider upgrading to a model like the NOCO GENIUS5 that adjusts voltage based on ambient conditions.

What’s the relationship between battery age and water consumption?

As batteries age (typically after 3+ years), water loss accelerates due to:

- Plate corrosion increasing internal resistance

- Reduced electrolyte capacity holding more heat

- Weaker cells requiring longer charge times

If your 4-year-old batteries suddenly need weekly refills, it’s often more cost-effective to replace them than continue adding water.

Are there any additives that can reduce water consumption?

While most additives are ineffective, two show measurable results:

- EDTA solutions (1% concentration) reduce mineral buildup

- Battery equalizers (like BE-4) can decrease loss by 15-20%

However, these are temporary solutions – proper charging and maintenance practices provide better long-term results without risking damage to battery chemistry.

How does water loss affect my golf cart’s performance?

Excessive water loss causes:

| Symptom | Performance Impact |

|---|---|

| Exposed plates | 20-30% power loss |

| Concentrated acid | Reduced battery life |

| Overheating | Faster capacity degradation |

A well-maintained water system can extend battery lifespan from 3 to 5 years in typical usage conditions.