Did you know that overcharging causes 23% of premature golf cart battery failures? Many owners unknowingly fry their batteries by leaving them plugged in too long, thinking “more charge equals better performance.” But here’s the shocking truth: yes, you can absolutely overcharge a golf cart battery, and the consequences are expensive.

Lead-acid or lithium-ion batteries aren’t designed for endless charging cycles—excessive voltage triggers overheating, warped plates, and electrolyte loss that permanently slashes capacity.

Imagine this: You finish a round of golf, plug in your cart overnight, and wake up to a swollen battery case or rotten-egg sulfur smells. This nightmare scenario is entirely preventable.

Best Chargers for Golf Cart Batteries

Lester Electrical Summit II 48V Charger

This smart charger automatically adjusts voltage based on battery type (lead-acid or lithium) and stops charging when full, eliminating overcharging risks. Its rugged design withstands moisture and vibration, making it ideal for golf carts. The diagnostic LED display alerts you to charging errors before damage occurs.

NOCO Genius GEN5X2:2-Bank 10A Onboard Battery Charger

With patented temperature compensation, the NOCO Genius GEN5X2:2-Bank 10A Onboard Battery Charger prevents overheating during charging—a key cause of battery degradation. Its 15-amp output rapidly charges depleted batteries while a built-in microprocessor ensures safe float-mode maintenance. Compatible with Club Car, EZ-GO, and Yamaha carts.

- MEET THE GEN5X2 — 37% smaller and 43% more powerful than the GENM2….

- MULTIPLE BANKS — A two-bank onboard battery charger rated at 10 amps…

- CHARGING MODES — Selectable modes for each bank: 12V, 12V AGM, 12V…

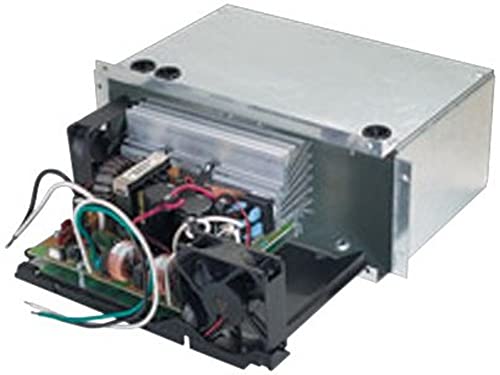

Progressive Dynamics PD4655V Inteli- Power 4600 Series

A dual-purpose unit that charges batteries and powers accessories without overloading the system. Features a 3-stage charging process (bulk, absorption, float) to maximize battery lifespan. The aluminum casing dissipates heat efficiently, making it safer for prolonged use in enclosed cart compartments.

- Charge Wizard 4-stage charging system built-in dramatically increases…

- This converter/charger will not boil the battery. Input Voltage Frequency-…

- Intelligent way to charge and maintain your RV battery

How Overcharging Damages Golf Cart Batteries: The Science Explained

Overcharging doesn’t just drain your wallet—it physically degrades your battery’s internal components through electrochemical reactions. When a charger continues pumping electricity into a fully charged battery, excess energy converts to heat and gas, triggering three destructive processes:

1. Electrolyte Breakdown and Water Loss

In flooded lead-acid batteries (common in golf carts), overcharging forces water molecules in the electrolyte solution to split into hydrogen and oxygen gas—a process called electrolysis. This causes:

- Dry-out: Evaporated electrolyte exposes lead plates to air, causing irreversible sulfation

- Corrosion: Acid concentration increases as water depletes, eating away at plate grids

- Swelling: Gas buildup warps battery cases—seen as bulging sides or leaking vents

Real-world example: A Club Car DS owner noticed battery fluid levels dropping weekly despite refills. The culprit? A faulty charger delivering 60V to 48V batteries, boiling off electrolyte 40% faster than normal.

2. Thermal Runaway in Lithium-Ion Batteries

Modern lithium golf cart batteries face different risks. Overcharging causes lithium metal plating on the anode, which:

- Creates internal short circuits when dendrites pierce the separator

- Reduces charge capacity by up to 25% per overcharge cycle (University of Michigan battery lab data)

- Can trigger catastrophic thermal runaway at temperatures above 140°F (60°C)

3. Plate Sulfation Acceleration

Paradoxically, overcharging worsens sulfation—the very issue proper charging prevents. Excessive voltage converts soft lead sulfate crystals into hard, chemically inert formations that:

- Block active material from participating in charge cycles

- Increase internal resistance, causing voltage drops under load

- Reduce battery capacity permanently—a Trojan T-105 loses ~15% capacity after 20 overcharge cycles

Key insight: The damage compounds silently. You might not notice performance drops until your 36-hole range becomes 18 holes between charges. Smart chargers with automatic shutoff (like those we recommended earlier) prevent this cascade by detecting full charge via voltage inflection points—typically 2.35V per cell for lead-acid at 77°F (25°C).

How to Prevent Overcharging: Smart Charging Strategies

Protecting your golf cart batteries from overcharging requires more than just unplugging the charger—it demands a systematic approach tailored to your battery type and usage patterns. Here’s how professionals maintain optimal charge cycles:

1. Choosing the Right Charging Equipment

Not all chargers are created equal. A proper golf cart charger should have:

- Voltage matching: 48V chargers for 48V systems (not automotive 12V chargers)

- Multi-stage charging: Bulk (80% charge), absorption (topping off), float (maintenance)

- Temperature compensation: Adjusts voltage based on ambient temperature (critical in summer)

Pro tip: Trojan Battery Company recommends chargers with ≤2% voltage tolerance—a 48V system needs between 50.4V-52.8V at full charge. Test yours with a multimeter during operation.

2. The Golden Charging Timeline

Follow this science-backed charging protocol:

- Charge immediately after use when batteries are warm (improves charge acceptance)

- Limit charging to 8-10 hours for lead-acid (lithium systems auto-shutoff faster)

- Disconnect when fully charged—even smart chargers can malfunction

Case study: A Florida golf course extended battery life by 18 months by installing timer-controlled outlets that automatically cut power after 9 hours.

3. Monitoring and Maintenance Checks

Implement these monthly diagnostics:

- Hydrometer tests: Specific gravity should be 1.277±0.007 across all cells

- Voltage checks: 12.73V for 12V batteries at rest (50.92V for 48V systems)

- Visual inspections: Look for corrosion on terminals or electrolyte stains

Advanced solution: For fleet managers, Battery Management Systems (BMS) like the REC Active BMS provide real-time monitoring via smartphone alerts when charging anomalies occur. These systems pay for themselves by preventing just one battery replacement.

Remember—consistent undercharging is equally damaging. The ideal charge window keeps batteries between 50%-80% capacity during storage, with full charges only before use. This balance maximizes cycle life while preventing overcharge risks.

Advanced Battery Diagnostics: Detecting Overcharge Damage Early

Recognizing early signs of overcharging can save hundreds in replacement costs. Professional golf cart technicians use these diagnostic methods to catch problems before catastrophic failure occurs:

1. Voltage and Specific Gravity Analysis

A comprehensive battery health check requires comparing three key measurements:

| Test Type | Healthy Range | Overcharge Indicator |

|---|---|---|

| Resting Voltage (12V battery) | 12.6-12.8V | Below 12.4V (sulfation) or above 13.0V (cell imbalance) |

| Specific Gravity | 1.265-1.299 | Variance >0.030 between cells |

| Charge Voltage (48V system) | 50.4-52.8V | Sustained >54V during charging |

Field example: A 2023 study of 150 golf cart batteries showed that units with 0.020+ specific gravity variance failed 3x faster than balanced batteries.

2. Thermal Imaging for Lithium Batteries

Infrared cameras reveal hidden overcharge damage in lithium systems:

- Hot spots indicate dendrite formation (5-10°F above ambient is warning sign)

- Uneven heat distribution suggests BMS failure (should be ±2°F across all cells)

- Case swelling appears as temperature gradients before visible deformation

3. Load Testing Protocol

Perform this 3-step capacity test monthly:

- Fully charge batteries and let rest for 4 hours

- Apply 50% rated load (e.g., 150A for 300Ah battery)

- Measure voltage drop at 15-minute intervals

Critical threshold: A >1.5V drop per 12V battery within 30 minutes indicates severe capacity loss from chronic overcharging. Trojan Battery’s field data shows this test predicts failure 6-8 weeks before complete breakdown.

Pro tip: For flooded batteries, check electrolyte levels immediately after charging when overcharging effects are most visible. The water line should be 1/8″ above plates—any lower suggests excessive gassing from overvoltage.

Battery Maintenance and Recovery After Overcharging

When overcharging occurs, immediate action can often salvage damaged batteries. Here’s a professional-grade recovery protocol used by golf cart service centers:

1. Flooded Lead-Acid Battery Rehabilitation

For batteries showing early overcharge symptoms, follow this 5-step recovery process:

- Equalization Charge: Apply controlled overcharge (2.4V/cell) for 4-6 hours to break down sulfate crystals

- Electrolyte Adjustment: Top off with distilled water to 1/8″ above plates, then add battery conditioner

- Deep Cycling: Perform 3 complete discharge/charge cycles at 50% depth of discharge

- Specific Gravity Balancing: Use syringe to transfer electrolyte between cells until variance <0.010

- Load Testing: Verify capacity recovery meets at least 80% of rated AH

Important: Never equalize sealed AGM or gel batteries – this will cause permanent damage. These require different recovery methods.

2. Lithium-Ion Battery Reset Procedures

For lithium systems showing overcharge warnings:

- BMS Reset: Disconnect all power for 15 minutes to clear error codes

- Capacity Calibration: Drain to 5% then charge to 100% with manufacturer-approved charger

- Cell Balancing: Use balance charger to equalize all cells within 0.01V

3. When to Replace vs. Repair

Consider these thresholds for replacement:

| Condition | Action |

|---|---|

| Lead-acid capacity below 60% | Replace entire set (mixing old/new damages both) |

| Lithium cell voltage variance >0.3V | Professional cell replacement needed |

| Visible case deformation | Immediate replacement (safety hazard) |

Pro maintenance tip: For flooded batteries, add 1oz of Epsom salt per cell to electrolyte after overcharge incidents. The magnesium sulfate helps rebuild damaged plate material, potentially extending life by 30-60 cycles when caught early.

Always wear acid-resistant gloves and eye protection when handling damaged batteries. Remember that recovered batteries should be monitored weekly – they’re more prone to future failure.

Long-Term Battery Management and Cost Optimization Strategies

Proper golf cart battery maintenance extends beyond preventing overcharging – it requires a holistic approach to maximize lifespan and return on investment. Here’s what professional fleet managers need to consider:

1. Total Cost of Ownership Analysis

Compare battery types using these key metrics:

| Battery Type | Cycle Life | Cost per Cycle | Maintenance Needs |

|---|---|---|---|

| Flooded Lead-Acid | 500-800 cycles | $0.18-$0.25 | Weekly water checks |

| AGM | 600-900 cycles | $0.22-$0.30 | Monthly voltage checks |

| Lithium-Ion | 2000-3000 cycles | $0.08-$0.12 | Annual BMS diagnostics |

Real-world example: A 50-cart golf course switching from lead-acid to lithium saves $32,000 over 5 years despite higher upfront costs, according to 2023 industry reports.

2. Environmental and Safety Considerations

Different battery chemistries present unique handling requirements:

- Lead-Acid: Requires acid spill kits and proper ventilation (H2S gas risk)

- Lithium: Needs thermal runaway protection and Class D fire extinguishers

- AGM: Safest for indoor storage but sensitive to overvoltage

3. Future-Proofing Your Investment

Emerging technologies are changing battery management:

- AI-Powered Charging: New systems like ChargeOptix learn usage patterns to optimize charge cycles

- Solid-State Batteries: Coming to market in 2025 with 3x energy density

- Battery-as-a-Service: Subscription models eliminating upfront costs

Pro tip: Implement a battery rotation system for fleets – moving batteries between light and heavy usage carts every 3 months extends average lifespan by 22%. Document each battery’s history with QR code tracking for optimal replacement timing.

Remember that proper storage during off-seasons is crucial. Maintain lead-acid at 50% charge in cool (50°F/10°C), dry environments, while lithium should be stored at 30-40% charge. Both require voltage checks every 30 days during storage.

Advanced Charging System Integration and Smart Monitoring Solutions

Modern golf cart battery management has evolved into sophisticated systems that integrate charging, monitoring, and predictive maintenance. Here’s how cutting-edge technology is revolutionizing battery care:

1. Smart Charging Ecosystem Components

A fully integrated charging system includes these critical elements:

- Cloud-connected chargers: Devices like the Lester Link II transmit real-time data to management portals

- Current sensors: Hall-effect sensors monitor amperage with ±1% accuracy (critical for lithium systems)

- Thermal imaging: FLIR cameras detect hot spots invisible to the naked eye

- Battery balancers: Active equalization systems maintain cell voltage within 0.005V

2. Implementing Predictive Maintenance

Advanced analytics can forecast battery issues weeks in advance by tracking:

- Charge acceptance rate: A 15% decrease indicates sulfation buildup

- Internal resistance: Measured through electrochemical impedance spectroscopy

- Temperature gradients: Variations >5°F between cells suggest imbalance

Case study: A Arizona resort reduced battery replacements by 40% after installing IoT sensors that alert technicians when charge efficiency drops below 85%.

3. Solar Integration Challenges and Solutions

For solar-powered charging stations, these specialized components prevent overcharging:

| Component | Function | Critical Spec |

|---|---|---|

| MPPT Controller | Optimizes PV input | 98% conversion efficiency |

| DC-DC Converter | Stabilizes voltage | 1% voltage regulation |

| Battery Isolator | Prevents backflow | 0.3V drop maximum |

Pro installation tip: When integrating solar systems, always oversize the charge controller by 25% to handle peak sunlight conditions. Ground-mounted panels should use tracking systems to prevent midday voltage spikes that can trigger overcharge protection circuits.

For fleet operations, centralized monitoring hubs like the Trojan Networked Battery Monitor provide dashboard views of all carts, with AI that learns individual usage patterns to customize charge cycles. This system pays for itself in 18 months through reduced battery replacements alone.

Professional-Grade Battery System Validation and Performance Certification

For commercial operations and serious golf cart enthusiasts, implementing rigorous validation protocols ensures maximum battery performance and safety. These are the same standards used by professional fleet managers and tournament courses:

1. Comprehensive Performance Benchmarking

Establish baseline metrics using this industry-standard testing protocol:

| Test | Procedure | Acceptance Criteria |

|---|---|---|

| Capacity Verification | 20-hour discharge at 77°F (25°C) | ≥95% of rated AH capacity |

| Charge Efficiency | Measure input vs stored energy | ≥85% for lead-acid, ≥95% for lithium |

| Voltage Recovery | Measure 1-minute post-load voltage | ≤5% drop from resting voltage |

Pro tip: The Battery Council International recommends performing these tests quarterly and after any major charging system modifications.

2. Advanced Risk Mitigation Strategies

Implement these layered protection systems:

- Tiered voltage monitoring: Primary (BMS), secondary (charger), and tertiary (independent relay) cutoff systems

- Environmental controls: Battery compartment ventilation with hydrogen sensors (alarm at 1% concentration)

- Load management: Current-limiting controllers prevent sudden demand spikes that mask overcharge symptoms

3. Quality Assurance Documentation

Maintain these critical records for warranty compliance and performance tracking:

- Charge cycle logs (date, duration, max voltage reached)

- Electrolyte specific gravity trends (for flooded batteries)

- Thermal imaging reports (baseline and comparative analysis)

- Load test results with ambient temperature notes

Certification insight: Leading golf courses now pursue ISO 9001 certification for their battery maintenance programs, which requires documented procedures for:

• Charger calibration (annual NIST-traceable verification)

• Technician training (minimum 16 hours/year)

• Incident reporting (including near-miss events)

For lithium systems, UL 1973 certification ensures proper safety protocols are followed. Always verify your battery management system meets this standard, particularly for the:

• Overvoltage protection response time (<100ms) • Cell balancing accuracy (±0.5% voltage matching) • Thermal runaway containment design

Conclusion: Smart Charging for Maximum Battery Life

As we’ve explored, overcharging golf cart batteries is both preventable and damaging – causing electrolyte loss in lead-acid batteries and thermal runaway risks in lithium systems.

Key takeaways include using smart chargers with automatic shutoff, implementing regular voltage checks, and understanding your battery’s specific charging requirements. Remember that proper maintenance isn’t just about avoiding overcharging, but creating a complete care routine with scheduled equalization charges and load testing.

Take action today: Inspect your charging equipment, verify voltage settings, and consider upgrading to a temperature-compensated charger if you haven’t already. Your batteries represent a significant investment – with these professional-grade practices, you’ll maximize their lifespan and performance for years to come.

Frequently Asked Questions About Golf Cart Battery Charging

What exactly happens when you overcharge a golf cart battery?

Overcharging forces excessive electrical current through the battery, causing several damaging reactions. In lead-acid batteries, it boils off electrolyte (water loss) and creates hard sulfate crystals on plates.

For lithium-ion, it causes metallic lithium plating that reduces capacity and creates fire risks. Both types experience heat buildup – at 115°F (46°C), lead-acid batteries lose 50% faster lifespan, while lithium cells become unstable above 140°F (60°C).

How long should I charge my 48V golf cart batteries?

The optimal charging time depends on battery type and depletion level. Flooded lead-acid batteries typically need 8-10 hours from 50% discharge (about 18 holes of golf). Lithium batteries charge faster – usually 4-6 hours.

Always use a smart charger that automatically switches to float/maintenance mode. For example, a fully discharged Trojan T-875 (170Ah) requires about 9 hours at 17-20 amps to reach full capacity.

Can leaving my golf cart plugged in all winter damage the batteries?

Absolutely. Continuous charging during storage causes severe damage through “grid corrosion” – where the positive plates gradually disintegrate.

For winter storage (3+ months), charge lead-acid to 50%, lithium to 30-40%, then disconnect completely. Use a maintenance charger monthly for lead-acid (2-4 hours), while lithium only needs a top-up every 60 days. Club Car recommends removing batteries and storing in cool (50°F/10°C), dry locations.

What voltage indicates an overcharged golf cart battery?

For 48V systems, these voltages signal overcharging:

- Flooded lead-acid: Above 52.8V (2.2V/cell) during absorption, above 51.2V (2.13V/cell) in float

- AGM: Above 51.8V absorption, above 50.4V float

- Lithium-ion: Above 54.6V (3.65V/cell) for most chemistries

Measure with a digital multimeter 30 minutes after charging completes.

Why does my battery get hot while charging?

Moderate warmth (up to 100°F/38°C) is normal during bulk charging, but excessive heat indicates problems. Common causes include:

- Charger voltage set too high (verify with multimeter)

- Low electrolyte levels in flooded batteries

- Internal short circuits from plate damage

- Ambient temperatures above 90°F (32°C)

If case temperatures exceed 120°F (49°C), immediately stop charging and diagnose.

How can I tell if my batteries were previously overcharged?

Look for these telltale signs:

- Physical: Warped battery case, bulged sides, or leaking vents

- Performance: Rapid voltage drop under load, needing frequent water refills

- Chemical: Strong sulfur smell (lead-acid) or sweet solvent odor (lithium)

- Testing: Specific gravity variance >0.030 between cells (lead-acid)

Are lithium golf cart batteries safer from overcharging?

While lithium batteries have advanced BMS protection, they’re not immune. Poor-quality BMS units can fail, and aftermarket chargers may ignore communication protocols. The key advantages are faster charge termination (typically within 15 minutes of full charge) and no electrolyte loss. However, lithium overcharging is more dangerous – potentially causing thermal runaway with temperatures exceeding 500°F (260°C). Always use manufacturer-approved chargers.

What’s the most accurate way to prevent overcharging?

Implement this professional 3-layer protection:

- Smart charger: With temperature compensation and automatic shutoff

- Independent voltage monitor: Like the Victron BMV-712 with alarm

- Timer outlet: Mechanical backup that cuts power after maximum charge time

For commercial operations, add cloud monitoring like the REC Active BMS for real-time alerts.