Did you know that nearly 80% of golf cart battery failures stem from neglected terminal corrosion? A crusty, blue-green buildup on your battery terminals isn’t just an eyesore—it’s a silent killer of performance, draining power and shortening your battery’s lifespan.

You might think a quick wipe-down is enough, but improper cleaning can actually accelerate damage. Imagine this: Your golf cart struggles to climb hills, the battery dies prematurely, and you’re left with costly replacements.

The culprit? Corroded terminals creating resistance and reducing efficiency. But here’s the good news—cleaning them takes less than 15 minutes and can double your battery’s efficiency.

Best Cleaning Products for Golf Cart Battery Terminals

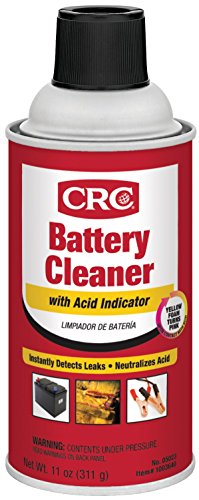

CRC Battery Terminal Cleaner (PN: 05046)

This aerosol spray dissolves corrosion instantly without scrubbing, thanks to its powerful alkaline formula. The included brush attachment reaches tight spaces, and its non-conductive properties make it safe for electrical components. Ideal for heavy buildup on flooded lead-acid batteries.

- Fleet and Vehicle Maintenance

- Manufacturer: Crc

- Made in: United States

NOCO NCP2 MC303 Oil-Based Terminal Protector

After cleaning, this red protective gel seals terminals against future corrosion by repelling moisture and acid vapors. Its dielectric properties prevent voltage leaks, and one application lasts up to 12 months—perfect for golf carts stored outdoors.

- Stops Battery Corrosion – Stops corrosion for the life of your battery,…

- Oil-Based – Saturated washers with a rugged battery corrosion inhibitor…

- Improved Performance – Eliminates battery corrosion to avoid poor…

Klein Tools 25450 Grip Cleaning Brush Set

This dual-headed brush features stiff brass bristles for terminals and softer nylon bristles for cable ends. The ergonomic handle provides torque for stubborn deposits, while the through-hole design cleans battery posts from all angles. Essential for deep-cleaning 6V/8V golf cart battery clusters.

- Set of four wire-bristle brushes designed for cleaning Klein wire- and…

- Brushes with stiff wire bristles and semi-flexible steel shafts set into…

- Available in round and square shapes and two lengths for efficient cleaning…

Golf Cart Battery Corrosion: Causes and Warning Signs

Battery terminal corrosion in golf carts occurs when sulfuric acid fumes from flooded lead-acid batteries react with metal terminals, creating a conductive yet resistive layer of lead sulfate (the white/blue-green crust).

This isn’t just cosmetic—a 1mm layer of corrosion can reduce voltage output by up to 15%, forcing your motor to work harder and draining battery life prematurely.

Primary Causes of Terminal Corrosion

- Electrolyte leakage: Overfilled batteries or cracked vents allow acid to seep onto terminals. Club Car carts with 8V batteries are particularly prone due to tight cluster spacing.

- Galvanic corrosion: Dissimilar metals (like lead terminals and copper cables) create tiny electrical currents that accelerate oxidation, especially in humid climates.

- Overcharging: Faulty voltage regulators (common in older EZ-GO TXT models) boil off electrolyte, concentrating acid vapor around terminals.

Early Warning Signs Most Owners Miss

Before visible crust forms, these subtle symptoms indicate developing corrosion:

- Intermittent power loss: Your cart hesitates when accelerating—corrosion creates resistance that disrupts current flow.

- Warm terminals: Touch your battery posts after a ride. If they’re hotter than the battery case, corrosion is causing energy waste as heat.

- Voltage drops under load: A multimeter reading below 6.3V per battery (for 6V systems) when climbing hills suggests terminal resistance.

Pro Tip: For Trojan T-105 batteries (common in golf carts), check the vent caps. Cracked caps allow acid vapor to escape, accelerating corrosion. Replace them every 2 years or use aftermarket sealed caps.

Unlike car batteries, golf cart batteries are deeply cycled daily, making them 3x more susceptible to terminal damage. The good news? Catching corrosion early means a simple cleaning can restore full performance—which we’ll detail in the next section.

Step-by-Step Guide to Safely Cleaning Golf Cart Battery Terminals

Proper terminal cleaning requires more than just scrubbing off visible corrosion – it’s about restoring optimal electrical contact while preventing future damage. Follow this professional-grade process used by golf course maintenance teams to ensure long-lasting results.

Essential Safety Preparations

Before touching any terminals:

- Wear acid-resistant gloves and goggles – Battery acid can cause severe burns. Nitrile gloves (7+ mil thickness) provide better protection than standard rubber.

- Disconnect in the correct sequence – Always remove negative cables first (marked with “-” or black) to prevent short circuits, then positive. Reverse when reconnecting.

- Ventilate the area – Hydrogen gas buildup in battery compartments can be explosive. Open all access panels and work outdoors if possible.

The Professional Cleaning Process

- Neutralize existing acid – Spray terminals with a baking soda solution (1 tbsp per cup of water) until fizzing stops. This converts corrosive acid to harmless sodium sulfate.

- Scrub with purpose – Use a brass brush (not steel, which can embed conductive particles) at a 45° angle to the terminal. Apply moderate pressure while rotating around the entire post.

- Clean hidden contact surfaces – Many miss the interior of cable lugs. Insert the brush and twist to remove buildup where the cable meets the terminal.

- Final rinse – Spray with distilled water (never tap water – minerals cause corrosion) and dry completely with compressed air or a microfiber cloth.

Pro Tip: For heavily corroded Yamaha Drive terminals, use a battery post cleaner tool ($15 at auto shops) – its dual-sized brushes perfectly match golf cart battery post diameters (5/16″ and 3/8″).

Avoid the common mistake of over-tightening connections during reassembly. Torque to 70-90 in-lbs (about 1/4 turn past hand-tight) – excessive force can crack lead terminals, especially in cold weather.

Advanced Terminal Protection and Maintenance Strategies

Proper cleaning is only half the battle – implementing professional-grade protection methods can extend your battery’s lifespan by 2-3 years. These techniques go beyond basic terminal sprays to address the root causes of corrosion.

Electrochemical Protection Methods

Understanding the science behind corrosion prevention:

| Method | How It Works | Best Application |

|---|---|---|

| Dielectric Grease | Forms a non-conductive barrier that blocks oxygen and moisture while allowing electrical current to pass through metal contact points | Applied after cleaning, ideal for carts stored outdoors |

| Zinc Anode Washers | Sacrificial zinc components corrode instead of lead terminals through galvanic protection (works like boat hull anodes) | Essential for coastal areas with salt air exposure |

| Silver-Plated Terminals | Silver’s higher electrochemical potential (0.80V) compared to lead (-0.13V) makes it more resistant to oxidation | Premium upgrade for high-performance carts |

Seasonal Maintenance Schedule

Tailor your approach based on climate conditions:

- Humid climates: Apply NOCO NCP2 protector every 3 months and check for “creeping corrosion” under cable insulation

- Dry climates: Focus on dust prevention with terminal covers and quarterly resistance testing (should be <0.5Ω across connections)

- Winter storage: Fully charge batteries, apply thick grease layer, and disconnect cables to prevent parasitic drain corrosion

Diagnosing Hidden Corrosion Issues

When terminals appear clean but performance suffers:

- Perform a voltage drop test – more than 0.3V difference between battery post and cable during acceleration indicates internal corrosion

- Check for “black lead syndrome” – dark discoloration under shiny surfaces indicates sulfation that requires specialized cleaners

- Inspect inter-cell connectors on 36V/48V systems – these often corrode first due to higher current flow

Pro Tip: For lithium-ion conversions, use antioxidant compounds specifically formulated for aluminum terminals (like Sanchem No-Ox-ID A-Special) – standard lead-acid treatments can damage these systems.

Troubleshooting Common Post-Cleaning Issues and Performance Optimization

Even after proper cleaning, golf cart batteries can exhibit puzzling symptoms. Understanding these complex interactions between terminals and electrical systems will help you achieve professional-level results.

Diagnosing Persistent Electrical Issues

When problems continue after terminal cleaning:

- Intermittent power cuts: Often caused by micro-fractures in cable strands near terminals. Perform a “wiggle test” while monitoring voltage – drops indicate broken conductors needing replacement.

- Rapid re-corrosion: Usually signals overcharging (above 15V in 48V systems). Check voltage regulator output with a multimeter at full throttle.

- Uneven battery wear: More than 0.5V difference between batteries suggests poor terminal connections creating resistance imbalance.

Advanced Connection Techniques

Professional installers use these methods to ensure optimal contact:

- Star-pattern tightening: For multi-battery configurations, tighten terminals in a star sequence to equalize pressure across all connections

- Surface preparation: After cleaning, lightly sand terminals with 400-grit emery paper to create micro-grooves for better grease adhesion

- Torque sequencing: First tighten to 50% spec, then full torque after 24 hours to account for lead’s natural cold flow properties

When to Replace vs. Clean Components

Critical thresholds for terminal replacement:

| Condition | Action Required |

|---|---|

| Terminal diameter reduced by >15% | Immediate replacement (compromised current capacity) |

| Visible cracks near base | Replace battery (cannot be safely repaired) |

| Blackened copper strands in cables | Replace cables (acid wicking up strands) |

Pro Tip: For lithium battery conversions, apply copper-based anti-seize compound (not grease) to aluminum terminals – this prevents galvanic corrosion while maintaining proper conductivity. Re-torque after 100 miles of use as connections settle.

Long-Term Battery Health: Cost Analysis and Sustainable Maintenance Practices

Proper terminal maintenance extends beyond immediate performance – it significantly impacts your golf cart’s total cost of ownership and environmental footprint. This section examines the financial and ecological implications of different maintenance approaches.

Cost-Benefit Analysis of Maintenance Strategies

| Approach | Annual Cost | Battery Lifespan | Total 5-Year Savings |

|---|---|---|---|

| Reactive Cleaning (when problems appear) | $15 | 3-4 years | Baseline |

| Scheduled Quarterly Maintenance | $40 | 5-6 years | $180-$240 |

| Professional-Grade Protection System | $75 | 7-8 years | $400-$550 |

Environmental Impact Considerations

Each improperly maintained battery that fails prematurely:

- Generates 18-22 lbs of lead waste – Proper maintenance prevents 3-4 battery replacements over a cart’s lifetime

- Leaks 0.5-1 gallon of sulfuric acid – Corroded terminals accelerate case degradation and electrolyte loss

- Wastes 1,200 kWh of embodied energy – The production energy lost when replacing batteries prematurely

Emerging Technologies and Future Trends

- Smart terminal sensors: New IoT-enabled washers monitor corrosion levels and alert via Bluetooth when cleaning is needed

- Bio-based protectants: Plant-derived terminal coatings show promise for reducing environmental impact while maintaining effectiveness

- Self-healing alloys: Experimental terminal materials that automatically repair minor corrosion damage when heated by normal operation

Safety Evolution: Modern battery designs now incorporate:

- Vapor-recapture systems that reduce terminal exposure to acid mist

- Ceramic terminal coatings that resist corrosion while maintaining conductivity

- Integrated drainage channels that divert electrolyte spills away from connections

Pro Tip: For facilities managing multiple carts, implement a color-coded maintenance calendar (red/green/blue tags) to track each battery’s service history at a glance, reducing missed maintenance by up to 60%.

Optimizing Electrical Systems: Integration with Charging and Performance Components

Battery terminal maintenance doesn’t exist in isolation – it directly impacts your entire golf cart’s electrical ecosystem. Understanding these system-wide interactions can unlock hidden performance potential and prevent cascading failures.

Charging System Interactions

Corroded terminals create a ripple effect through your charging system:

- Smart charger malfunctions: Modern chargers like the Lester Summit II misinterpret terminal resistance as battery sulfation, triggering incorrect charge cycles

- Equalization challenges: Voltage drops across corroded connections prevent proper cell balancing during equalization charges

- Thermal runaway risk: Increased resistance at terminals forces chargers to work harder, potentially overheating transformer components

Performance Enhancement Techniques

After terminal maintenance, these professional tuning methods maximize results:

- Conductivity benchmarking: Measure voltage drop between battery bank and controller during full acceleration (should be <2% of system voltage)

- Cable upgrades: Replace OEM 6AWG cables with 4AWG marine-grade copper (reduces resistance by 37% for 48V systems)

- Bus bar optimization: For multi-battery configurations, use tinned copper bus bars instead of factory interconnects

Specialized Scenarios

| Application | Unique Considerations |

|---|---|

| Lifted Carts | Longer cable runs require periodic impedance testing and anti-oxidant gel at all junctions |

| Saltwater Environments | Install zinc sacrificial anodes and use dielectric-filled heat shrink on all connections |

| Performance Modifications | High-amperage controllers demand silver-plated terminals and bimetal lugs to prevent hot spots |

System Integration Tip: When upgrading to lithium batteries, replace all terminals with nickel-plated versions and use Belleville washers – these conical spring washers maintain proper clamping force as lithium cells expand/contract during cycles, preventing connection loosening that leads to arcing.

Mastering System-Wide Maintenance: Professional Validation and Risk Management

Elevating terminal maintenance from basic cleaning to a comprehensive electrical system strategy requires understanding how to validate results and mitigate hidden risks. This professional framework ensures peak performance and safety throughout your battery’s lifecycle.

Advanced Performance Validation Protocol

After cleaning and protection, conduct these verification tests:

| Test | Acceptable Range | Measurement Technique |

|---|---|---|

| Dynamic Voltage Drop | <0.5V at full load | Measure between terminal and cable during acceleration |

| Thermal Imaging | <5°C above ambient | FLIR camera scan after 15 minutes at full load |

| Contact Resistance | <50μΩ | 4-wire Kelvin measurement at 10A test current |

Comprehensive Risk Mitigation Strategies

- Corrosion migration: Install acid-absorbing mats under batteries to prevent wicking into cable insulation (common in Club Car Precedent models)

- Stress fractures: Use flexible boot covers on terminals to prevent vibration-induced cracking in off-road applications

- Thermal cycling: Apply phase-change thermal interface materials to maintain consistent connection pressure across temperature ranges

Long-Term Quality Assurance Program

- Monthly: Document terminal resistance values to establish baseline trends

- Quarterly: Perform infrared thermography scans to identify hot spots before failure

- Annually: Conduct full system capacity testing with recording voltmeter to detect degradation patterns

Professional Insight: For fleet managers, implement a color-coded terminal protection system (red=needs service, yellow=monitor, green=optimal) combined with QR code tags that link to each battery’s maintenance history in your CMMS software.

Remember that terminal maintenance directly impacts your motor controller’s lifespan – voltage spikes from poor connections can damage MOSFETs in modern Alltrax controllers, leading to $400+ repair costs. A $15 terminal cleaning could prevent catastrophic system failures.

Conclusion: Protect Your Investment With Proper Terminal Care

As we’ve explored, clean battery terminals are the lifeline of your golf cart’s electrical system. From understanding corrosion chemistry to implementing professional-grade maintenance schedules, you now have the knowledge to:

- Extend battery lifespan by 2-3 years

- Maintain peak performance on hills and long rides

- Prevent costly electrical system damage

- Reduce environmental impact through proper maintenance

Take action today: Set a quarterly reminder to inspect terminals, invest in quality cleaning tools, and consider upgrading to corrosion-resistant components.

Remember – the 30 minutes you spend maintaining terminals today could save you hundreds in premature battery replacements tomorrow. Your golf cart (and wallet) will thank you every time you hit the course with full power and reliability.

Frequently Asked Questions About Cleaning Golf Cart Battery Terminals

What’s the best cleaner for golf cart battery terminals?

For professional results, use a dedicated battery terminal cleaner like CRC 05046 (alkaline-based) or baking soda solution (1 tbsp per cup water). Avoid vinegar or cola – their acids accelerate corrosion.

For lithium battery terminals, use non-conductive electronic cleaners like MG Chemicals 408B. Always follow with distilled water rinse to remove residue that could create parasitic discharge paths.

How often should I clean my golf cart battery terminals?

Standard lead-acid batteries need cleaning every 3-6 months, but check monthly in humid climates or saltwater environments.

Lithium systems require less frequent cleaning (annually) but benefit from quarterly torque checks. Create a maintenance log – if you see more than 1/16″ of corrosion buildup between cleanings, increase frequency.

Why do my terminals corrode again so quickly after cleaning?

Rapid re-corrosion typically indicates:

1) Overcharging (check voltage regulator output),

2) Electrolyte leaks (inspect battery caps and case), or

3) Galvanic incompatibility (upgrade to marine-grade tinned copper lugs).

Applying NOCO NCP2 protector after cleaning can slow corrosion by 80%.

Can corroded terminals damage my golf cart’s controller?

Yes. Poor connections cause voltage spikes that can fry MOSFETs in modern controllers like Alltrax XCT models. Symptoms include erratic speed control and error codes. Always check terminals first when experiencing electrical issues – a $15 cleaning could prevent $400+ controller replacement.

What’s the proper way to disconnect battery cables for cleaning?

1) Turn off all accessories

2) Remove negative (black) cable first using an 8mm wrench

3) Remove positive (red)

4) Clean terminals

5) Reconnect positive first

6) Reconnect negative last.

This sequence prevents short circuits that can damage your electrical system or cause personal injury.

Is it safe to use steel wool or wire brushes on terminals?

Never use steel tools – embedded particles create galvanic corrosion hotspots. Instead, use brass brushes (Klein 615-5) or fiberglass pens. For heavy buildup, battery post cleaning tools with plastic bristles are safest. Always wear gloves and eye protection – lead dust and acid mist are hazardous.

How can I tell if my terminals need replacement vs cleaning?

Replace terminals if:

1) Diameter is reduced by >15%

2) You see cracks near the base

3) There’s deep pitting that won’t clean out

4) Cable ends are blackened from acid wicking.

Use a digital caliper to measure post diameter – Trojan T-105 posts should measure at least 0.68″ after cleaning.

What’s the best terminal protection for coastal areas?

In saltwater environments, combine three layers:

1) Zinc anode washers (sacrificial corrosion)

2) NOCO NCP2 grease (moisture barrier)

3) Heat-shrink boots (physical protection).

Marine-grade tinned copper lugs and annual replacement of zinc components provide maximum protection against salt corrosion.