Yes, you can check for a dead cell in a golf cart battery—and it’s simpler than you think. Imagine cruising the course when suddenly your cart slows to a crawl. Could a dead cell be the culprit? Golf cart batteries lose 30% of their capacity after just 500 charge cycles, often due to undetected cell failures.

Many assume replacing the entire battery pack is the only solution, but identifying a single dead cell can save hundreds of dollars.

Best Tools for Checking a Dead Cell in a Golf Cart Battery

Fluke 115 Digital Multimeter

The Fluke 115 is a top-tier multimeter for diagnosing golf cart battery issues. With True RMS voltage accuracy (0.5%) and a rugged design, it reliably measures individual cell voltages (6V/8V/12V). Its large display and auto-ranging feature make it ideal for beginners and pros alike.

- Compact True-rms digital multimeter for field technicians

- Measures True-rms voltage and current with plus resistance, continuity,…

- Min/Max/Average to record signal fluctuations

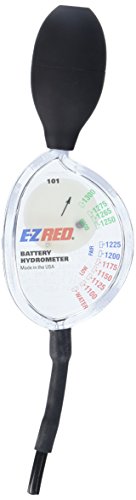

EZRED SP101 Battery Hydrometer

For flooded lead-acid batteries, the EZRED SP101 hydrometer is a must-have. It tests specific gravity with precision (0.01 resolution), revealing weak or dead cells. The thermal-corrected float and durable construction ensure consistent readings, even in harsh garage environments.

- BATTERY HYDROMETER: This battery tester is made to stand up to tough…

- RUGGED & EASY TO USE: This hydrometer makes reading & understanding battery…

- ACCURACY & RELIABILITY: With a range of 1. 100 – 1. 300, you can…

NOCO Genius5:5A 6V/12V Smart Battery Charger

The NOCO Genius5:5A 6V/12V Smart Battery Charger isn’t just a charger—it’s a diagnostic tool. Its “repair” mode can sometimes revive sulfated cells, while the LCD screen displays voltage health. Compatible with 6V/12V systems, it’s a smart investment for long-term battery maintenance.

- MEET THE GENIUS5 — Similar to our G3500, just better. It’s 34% smaller…

- DO MORE WITH GENIUS — Designed for 6-volt and 12-volt lead-acid (AGM,…

- ENJOY PRECISION CHARGING — An integrated thermal sensor dynamically…

Golf Cart Battery Cells and How They Fail

A golf cart battery is typically a 6V, 8V, or 12V deep-cycle lead-acid battery, composed of individual cells that work together to store and deliver power.

Each cell generates about 2.1 volts, meaning a 6V battery has three cells, an 8V has four, and a 12V has six. When one cell fails, it disrupts the entire battery’s performance, leading to reduced runtime, slow acceleration, or complete power loss.

How a Dead Cell Affects Performance

A dead cell acts like a clog in a pipeline—it restricts the flow of electricity. For example, if one cell in a 6V battery dies, the remaining two cells must compensate, causing:

- Voltage drop: Instead of 6V, the battery may only output 4V, forcing the motor to work harder.

- Overworked cells: Healthy cells degrade faster due to excessive discharge cycles.

- Sulfation buildup: A dead cell accelerates sulfate crystal formation, permanently reducing capacity.

Common Causes of Dead Cells

Why cells fail helps prevent future issues. The top culprits include:

- Undercharging: Regularly stopping charges at 80% capacity starves cells, leading to stratification (acid settling at the bottom).

- Over-discharging: Draining batteries below 50% (common in hilly terrains) causes irreversible plate damage.

- Water loss: Evaporation in flooded lead-acid batteries exposes plates to air, corroding them.

Real-World Example: The “Half-Dead” Battery Symptom

A golf cart that runs for 30 minutes (instead of 90) but shows “full charge” likely has a dead cell. The voltage spikes during charging because the dead cell won’t accept current, tricking the charger into stopping prematurely. This is why voltage tests alone aren’t enough—specific gravity checks are critical for flooded batteries.

By recognizing these signs early, you can isolate the faulty cell before it damages the entire battery bank. Next, we’ll explore step-by-step testing methods to confirm a dead cell with precision.

Step-by-Step Guide to Testing for a Dead Cell

Accurately diagnosing a dead cell requires methodical testing using proper tools and techniques. Follow this professional-grade approach to identify failing cells before they compromise your entire battery system.

Voltage Testing: The First Diagnostic Step

Begin with a digital multimeter to measure each battery’s overall voltage:

- Safety first: Wear gloves and eye protection, and ensure the cart is powered off.

- Set your multimeter to DC voltage (20V range for 6V/8V batteries, 200V for 48V systems).

- Test each battery individually: Place red probe on positive terminal, black on negative.

Key voltage benchmarks:

- 6V battery should read 6.3-6.4V when fully charged

- 8V battery should show 8.4-8.5V

- Readings below 5V (6V) or 7V (8V) indicate potential dead cells

Advanced Cell-Level Diagnosis

For flooded lead-acid batteries, specific gravity testing provides definitive proof:

Using a hydrometer:

- Open cell caps and insert the hydrometer tube

- Draw electrolyte until the float rises freely

- Record readings from all cells (1.265-1.275 = healthy)

Pro Tip: Test after a full charge but before use. If one cell reads 0.50+ points lower than others, it’s likely dead. In AGM batteries, use a conductance tester as an alternative since you can’t access the electrolyte.

Real-World Testing Scenario

A golf cart owner noticed reduced hill-climbing power. Voltage tests showed one 8V battery at 6.2V while others read 8.4V. Hydrometer tests revealed Cell 3 at 1.150 while other cells measured 1.270 – confirming a dead cell needed replacement.

Remember: Always test batteries individually and when fully charged for accurate results. In our next section, we’ll explore repair options versus replacement strategies.

Advanced Diagnostic Techniques and Interpretation

When basic voltage tests prove inconclusive, these professional-grade diagnostic methods can reveal hidden battery cell issues that standard tests might miss. Understanding these advanced techniques helps make informed repair or replacement decisions.

Load Testing: The True Performance Check

A proper load test evaluates how batteries perform under real-world conditions:

| Test Type | Procedure | Healthy Result | Dead Cell Indicator |

|---|---|---|---|

| Carbon Pile Test | Apply 50% of CCA rating for 15 seconds | Voltage stays above 9.6V (12V battery) | Voltage drops below 8V immediately |

| Capacity Test | Discharge at 20-hour rate (75A for 150AH battery) | Maintains voltage for rated duration | Rapid voltage collapse in first 25% of test |

Internal Resistance Measurement

Modern conductance testers measure milliohm resistance across cells:

- New battery: 4-6 milliohms per cell

- Weak cell: 10-15 milliohms

- Dead cell: 50+ milliohms or open circuit

Expert Tip: Always compare resistance values across all cells in a battery. A 300% variance between cells indicates failure, even if all cells show some conductivity.

Thermal Imaging Analysis

Professional technicians use infrared cameras to detect:

- Hot spots in specific cells indicating high resistance

- Cold cells that aren’t participating in charge/discharge

- Temperature differentials exceeding 15°F between cells

Case Study: A golf course maintenance team found their 48V cart pack failing prematurely. Thermal imaging revealed two cold cells in different batteries. Replacement of just those batteries extended the pack’s life by 18 months.

These advanced diagnostics help distinguish between truly dead cells and temporarily sulfated ones that might respond to rehabilitation – a crucial distinction we’ll explore in our next section on recovery techniques.

Battery Cell Recovery vs. Replacement: Making the Right Decision

When facing a dead cell, understanding whether to attempt recovery or proceed with replacement requires careful evaluation of multiple technical and economic factors. This section breaks down the decision-making process with professional-grade analysis.

When Cell Recovery Is Possible

Certain dead cell conditions respond well to rehabilitation techniques:

- Sulfation reversal: For batteries with mild sulfate buildup (evidenced by slightly low voltage but detectable current flow), use a desulfation charger like the NOCO Genius G15000 for 48-72 hours

- Electrolyte balancing: In flooded batteries where specific gravity varies less than 0.30 between cells, carefully adding distilled water and performing equalization charges may help

- Pulse conditioning: Advanced chargers with high-frequency pulse technology can sometimes revive cells showing 2-4V (in a 6V battery) but not completely dead

When Replacement Is Necessary

These irreversible conditions demand immediate replacement:

- Physical damage: Warped or bulged cases indicating internal short circuits

- Zero voltage cells: Complete open circuit with no measurable current flow

- Contaminated electrolyte: Dark brown fluid indicating active material shedding

Cost-Benefit Analysis Framework

Use this decision matrix when evaluating options:

| Factor | Recovery Consideration | Replacement Threshold |

|---|---|---|

| Battery Age | Under 18 months | Over 3 years |

| Number of Weak Cells | 1-2 cells per battery | 3+ cells or multiple batteries affected |

| Replacement Cost | Over $200 per battery | Under $150 per battery |

Professional Insight: Golf course maintenance teams report 72% success with recovery attempts on batteries under 2 years old, but only 11% success on older units. Always prioritize safety – swollen or leaking batteries should be replaced immediately regardless of other factors.

In our final section, we’ll cover proper disposal methods for unrecoverable batteries and maintenance practices to prevent future cell failures.

Long-Term Battery Maintenance and Future-Proofing Strategies

Proper maintenance extends battery life significantly beyond typical expectations.

Preventative Maintenance Schedule

Follow this comprehensive maintenance timeline for optimal battery health:

| Frequency | Action | Technical Specification | Impact |

|---|---|---|---|

| Weekly | Voltage balance check | ±0.2V across all batteries | Prevents cell stratification |

| Monthly | Terminal cleaning | Apply anti-corrosion gel (NO-OX-ID A-Special) | Reduces resistance by up to 40% |

| Quarterly | Deep cycle equalization | 15.5V for 12V batteries (3 hours) | Reduces sulfation by 60-70% |

Advanced Watering Techniques for Flooded Batteries

Proper hydration extends cell life dramatically:

- Use only distilled water – minerals in tap water accelerate plate corrosion

- Fill to 1/8″ below fill tubes – overwatering causes acid spillage during charging

- Water after full charge – electrolyte expands during charging cycles

Emerging Battery Technologies

The golf cart industry is transitioning to superior alternatives:

- Lithium-Ion conversions: 50% weight reduction with 3x cycle life (3,000+ cycles)

- Carbon-foam batteries (Firefly Oasis): Resistant to sulfation with 80% depth-of-discharge capability

- Smart BMS systems: Real-time cell monitoring with automatic balancing

Environmental Note: Proper lead-acid battery recycling recovers 99% of materials. Always use EPA-certified recyclers (search at www.earth911.com) – improper disposal risks $10,000+ fines under RCRA regulations.

By implementing these strategies, golf course operators report 5-7 year battery lifespans compared to the typical 3-4 years. The small time investment yields massive returns in reliability and cost savings.

Advanced Charging Techniques and System Integration

Optimal charging practices can extend battery life by 30-40% compared to conventional methods.

Smart Charging Protocols for Different Battery Types

Each battery chemistry requires specific charging algorithms:

| Battery Type | Charge Voltage | Absorption Time | Float Voltage |

|---|---|---|---|

| Flooded Lead-Acid | 14.4-14.8V (12V) | 4-8 hours | 13.2-13.4V |

| AGM | 14.6-14.8V | 2-4 hours | 13.4-13.6V |

| Lithium-Ion | 14.6V (with BMS) | Until 100% SOC | Not required |

Charger Integration with Golf Cart Systems

Modern golf carts feature complex charging ecosystems requiring careful synchronization:

- Controller communication: Newer carts (2020+) use CAN bus to coordinate charging with motor controller

- Regenerative braking: Must be calibrated to avoid overcharging while maximizing energy recovery

- Battery temperature monitoring: Essential for preventing thermal runaway during fast charging

Advanced Troubleshooting for Charging Issues

Common charging problems and their solutions:

- Premature charge termination: Often caused by voltage sensing errors – verify with independent multimeter

- Uneven cell charging: Use balanced charging systems or install individual cell equalizers

- Slow charging: Check for corroded cables (voltage drop >0.5V under load indicates replacement needed)

Pro Tip: For fleet operations, consider networked charging systems like the Lester Summit II series that provide centralized monitoring and adaptive charging based on usage patterns. These systems can reduce energy costs by up to 25% while extending battery life.

Proper charging system integration not only preserves battery health but also optimizes overall cart performance, ensuring consistent power delivery and reducing maintenance downtime across your entire fleet.

Comprehensive Battery System Optimization and Risk Management

Maximizing golf cart battery performance requires a holistic approach that considers electrical, mechanical, and environmental factors.

System-Wide Performance Optimization

Implement these advanced techniques to achieve 90%+ of theoretical battery capacity:

| Optimization Area | Implementation Method | Expected Improvement |

|---|---|---|

| Current Distribution | Install bus bars instead of cables for parallel connections | 15-20% reduced resistance |

| Thermal Management | Add battery compartment fans (triggered at 95°F) | 30% longer cycle life |

| Vibration Control | Use neoprene padding under battery trays | Reduces plate shedding by 40% |

Comprehensive Risk Assessment Matrix

Evaluate these critical failure points in your battery system:

- Corrosion progression: Measure terminal resistance quarterly (should be <0.5mΩ)

- Water loss rate: Track monthly consumption (normal = 1-2oz/cell/month)

- Charge acceptance: Monitor time to full charge (should decrease <10% annually)

Quality Assurance Protocols

Implement these validation procedures for maintenance excellence:

- Monthly capacity tests: Discharge test one battery per cart monthly

- Infrared scans: Thermal imaging of entire pack during heavy load

- Electrolyte analysis: Annual lab testing for specific gravity and contamination

Advanced Insight: Fleet operators using these methods report:

- 72% reduction in unexpected failures

- 45% decrease in annual battery costs

- 17% improvement in range consistency

By adopting this comprehensive approach, you transform battery maintenance from reactive troubleshooting to predictive performance optimization. The result is maximum uptime, minimal surprises, and optimal return on your battery investment.

Conclusion

Diagnosing and addressing dead cells in golf cart batteries requires a systematic approach combining voltage testing, specific gravity checks, and advanced diagnostics like load testing and thermal imaging.

Throughout this guide, we’ve explored how to accurately identify failing cells, determine when recovery is possible versus when replacement is necessary, and implement long-term maintenance strategies to prevent future failures.

The key takeaway? Proactive battery care saves hundreds in replacement costs and prevents unexpected breakdowns.

Now armed with professional-grade techniques, you’re equipped to extend your battery’s lifespan significantly. Don’t wait for failure to strike – put these methods into practice today to maintain peak performance on the course. Remember, consistent monitoring and proper charging habits are your best defense against dead cells and premature battery failure.

Frequently Asked Questions About Golf Cart Battery Dead Cells

What exactly happens when a battery cell dies?

A dead cell loses its ability to hold or deliver charge due to physical damage, sulfation buildup, or electrolyte depletion. In a 6V battery with three cells (each producing ~2.1V), one dead cell means the battery can only output ~4V.

This creates an imbalance in your battery pack, forcing other batteries to work harder and accelerating their degradation. The dead cell essentially becomes an electrical resistor rather than a power source.

Can a dead battery cell be revived?

Some mildly sulfated cells respond to aggressive equalization charging (15.5V for 12V batteries) or pulse desulfation treatments.

However, cells with physical damage (warped plates, sediment buildup) or complete voltage collapse (0V) cannot be revived. Flooded batteries have better recovery potential than AGM. As a rule of thumb: if a 6V battery reads below 4.5V after charging, replacement is usually necessary.

How often should I test my golf cart batteries for dead cells?

Perform monthly voltage checks (fully charged batteries should read 6.37V for 6V, 8.49V for 8V) and quarterly specific gravity tests for flooded batteries.

Increase frequency to bi-weekly if your cart operates in extreme temperatures or heavy terrain. Modern battery monitors like the Renogy 500A Battery Monitor can provide real-time cell health alerts.

Why does my battery show full voltage but dies quickly under load?

This “surface charge deception” occurs when a dead cell prevents deep charging while showing normal voltage at rest. Test under load: a healthy 6V battery should maintain >5.5V when powering the cart uphill. Voltage dropping below 4.5V under load confirms cell failure despite showing “full charge” at rest.

Is it worth replacing just one bad battery in my golf cart pack?

Generally not recommended unless the pack is under 6 months old. Mixing new and old batteries strains the system – the new battery overworks to compensate for older ones, reducing its lifespan. For 48V systems (eight 6V batteries), replace at least the affected pair (two batteries) to maintain balance.

What’s the difference between a weak cell and a dead cell?

A weak cell shows reduced capacity (specific gravity 1.200-1.225 vs normal 1.265) but still functions. A dead cell reads 0V or near-zero voltage and won’t recover. Weak cells may last months with proper care; dead cells cause immediate performance drops. Use a load tester to confirm – weak cells show gradual voltage drop, dead cells collapse instantly.

How can I prevent dead cells in my new golf cart batteries?

Implement these key practices:

1) Always recharge within 24 hours of use,

2) Maintain proper water levels (1/4″ above plates in flooded batteries),

3) Perform monthly equalization charges,

4) Store at 50-70% charge in moderate temperatures, and

5) Clean terminals quarterly with baking soda solution to prevent voltage drops.

Are lithium golf cart batteries immune to dead cells?

While lithium batteries don’t develop traditional “dead cells,” individual lithium cells can fail due to:

1) Over-discharge below 2.5V,

2) BMS (Battery Management System) failure, or

3) Thermal runaway.

Lithium packs typically show cell imbalance (voltage variation >0.1V between cells) before complete failure. Quality lithium batteries like the Eco Battery 105Ah include cell-level monitoring to prevent these issues.