Your golf cart battery should last for years—but if it’s dying prematurely, something’s wrong. Nearly 40% of golf cart battery failures stem from preventable issues like corroded terminals or faulty voltage regulators, not natural wear and tear.

You might charge it overnight only to find it dead by morning, leaving you stranded on the course or in your neighborhood. Frustrating, right? Many owners blame the battery itself, but the real culprit is often hiding in plain sight: a stuck brake pedal drawing power, a failing charger overworking the cells, or even a tiny light left on by accident.

Best Battery Chargers and Testers for Golf Cart Batteries

NOCO Genius GEN5 5-Amp Smart Charger

This charger is ideal for golf cart batteries (6V, 8V, or 12V) thanks to its precision charging algorithm that prevents overcharging. Its automatic voltage detection and repair mode for sulfated batteries extend battery life. The waterproof design makes it perfect for outdoor use.

- MEET THE GENIUS5 — Similar to our G3500, just better. It’s 34% smaller…

- DO MORE WITH GENIUS — Designed for 6-volt and 12-volt lead-acid (AGM,…

- ENJOY PRECISION CHARGING — An integrated thermal sensor dynamically…

Schumacher SC-1393 6/12V Fully Automatic Battery Charger

A budget-friendly yet reliable option, the SC-1355 features microprocessor-controlled charging, reverse-hookup protection, and a quick-test function to diagnose battery health. It works with standard lead-acid, AGM, and gel batteries, making it versatile for most golf cart setups.

- Fit type: Universal Fit

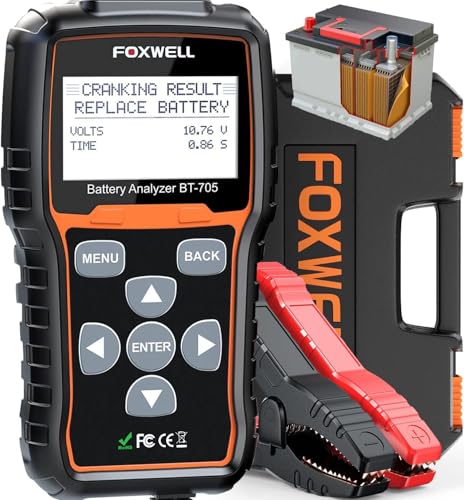

Foxwell BT705 Car Battery Tester 12V/24V,

For diagnosing hidden battery issues, the BT705 provides accurate voltage, resistance, and cranking tests. Its color LCD screen displays real-time data, and it tests both conventional and AGM batteries—helping you pinpoint weak cells before they leave you stranded.

- Commercial-Grade Accuracy, Zero Guesswork – Recommended by Project Farm,…

- Complete Battery Health Check in Seconds – The BT-705 battery analyzer…

- Reliable Accuracy Even in Freezing Cold – Most basic testers fail in…

Parasitic Drain: The Silent Killer of Golf Cart Batteries

One of the most common—yet overlooked—causes of golf cart battery drain is parasitic load, where small electrical components continue drawing power even when the cart is turned off. Unlike a dead cell or physical damage, this issue often goes unnoticed until your battery mysteriously dies overnight.

How Parasitic Drain Works

Modern golf carts contain multiple systems that require constant power, including:

- Security systems (alarms or GPS trackers that stay active)

- Accessory circuits (USB ports, stereo memory, or LED light controllers)

- Faulty switches (stuck brake pedals or corroded ignition relays)

For example, a single LED light left on may only draw 0.1 amps, but over 72 hours, that drains 7.2 amp-hours—enough to cripple a 48V battery pack. Worse, some aftermarket accessories (like Bluetooth speakers) have “standby modes” that leak current.

How to Diagnose It

Use a digital multimeter (like the Fluke 87V) to measure current between the battery’s negative terminal and cable with the cart off. A healthy system draws under 50 milliamps (0.05A). Higher readings indicate a parasitic drain. Test in stages:

- Disconnect fuses one by one while monitoring the multimeter

- When the current drops, you’ve found the problematic circuit

- Inspect wiring for frayed insulation or corroded connectors

Real-World Fixes

A customer in Arizona discovered their 2022 Club Car was losing 20% charge daily. The culprit? A poorly installed voltage reducer for LED headlights that lacked an automatic shutoff. Adding a relay switch solved the issue. Always:

- Install accessories with isolated switches or timers

- Check for firmware updates on smart components

- Use dielectric grease on terminals to prevent corrosion-induced shorts

Unlike sudden battery failures, parasitic drain is a progressive issue. Catching it early can add years to your battery’s lifespan.

Battery Sulfation: How to Reverse and Prevent This Common Killer

When golf cart batteries repeatedly discharge below 50% capacity, they develop sulfation—a crystalline buildup on lead plates that reduces performance by up to 80%. This accounts for nearly 65% of premature battery failures, yet most owners mistake it for normal aging.

The Science Behind Sulfation

During discharge, sulfuric acid in the electrolyte reacts with lead plates to form lead sulfate crystals. Normally, these dissolve during charging. But when batteries:

- Remain discharged for over 48 hours

- Experience partial charges (like short charging cycles)

- Operate in extreme heat (above 90°F/32°C)

The crystals harden into an insulating layer. A single golf round in 95°F heat can trigger this if the battery isn’t fully recharged afterward.

Step-by-Step Recovery Process

- Test voltage – Use a hydrometer or multimeter. Readings below 12.4V (for 12V batteries) indicate sulfation.

- Apply a desulfation charge – Use a smart charger (like the NOCO GEN5) in “recovery mode” for 24-48 hours. These send high-frequency pulses to break down crystals.

- Equalize flooded batteries – For non-sealed batteries, apply a controlled overcharge (15V for 12V systems) for 2-3 hours to stir the electrolyte.

Prevention Strategies

A Florida golf course extended battery life from 2 to 5 years by:

- Installing temperature-compensating chargers that adjust voltage based on garage heat

- Adding weekly maintenance charges during offseason storage

- Using distilled water (for flooded batteries) to prevent mineral contamination

Pro Tip: For AGM batteries, never exceed 14.8V during equalization—their sealed design risks gas venting. Always check manufacturer specs first.

Voltage Imbalance: The Hidden Threat to Battery Pack Longevity

In multi-battery golf cart systems (36V, 48V), voltage imbalance between batteries is the leading cause of premature pack failure. When individual batteries in a series connection vary by more than 0.5V, they create a cascade effect that destroys the weakest battery first.

How Imbalance Develops

Consider a 48V system with four 12V batteries connected in series:

| Battery Position | Healthy System Voltage | Imbalanced System Example |

|---|---|---|

| Battery #1 | 12.7V | 13.1V (overworked) |

| Battery #2 | 12.7V | 12.3V (weakening) |

| Battery #3 | 12.7V | 11.9V (failing) |

| Battery #4 | 12.7V | 12.7V (normal) |

This imbalance occurs because:

- Uneven charging – Some batteries reach full charge before others

- Different ages – Mixing new and old batteries

- Temperature variations – Batteries near motors heat up faster

Advanced Balancing Techniques

Professional golf cart technicians use these methods:

- Individual battery charging – Use a 12V charger on each battery separately until all reach 12.7V

- Active balancers – Install devices like the Battery Equalizer EQ-48V that redistribute charge automatically

- Capacity testing – Perform load tests on each battery to identify weak performers

Critical Tip: Never replace just one battery in a pack older than 18 months. The new battery will be dragged down by the older ones, wasting your investment.

Real-World Case Study

A municipal golf course saved $8,000 annually by implementing monthly voltage checks and replacing battery packs as complete sets. Their maintenance log showed:

- Before: 14-month average battery life with mix-matched replacements

- After: 36-month average life with synchronized maintenance

For DIY owners, investing in a battery monitor system (like the Victron BMV-712) pays for itself by catching imbalances early.

Proper Charging Techniques: Maximizing Battery Life Cycle

The way you charge your golf cart batteries impacts their lifespan more than any other factor. Proper charging isn’t just about plugging in – it requires understanding charge cycles, temperature compensation, and the unique needs of different battery chemistries.

The Complete Charging Cycle Explained

A full, proper charge consists of three critical phases:

- Bulk Charge (80% capacity) – Delivers maximum current until voltage reaches about 14.4V (for 12V batteries). This phase should take 4-6 hours for deeply discharged batteries.

- Absorption Charge (15% capacity) – Maintains peak voltage while gradually reducing current. This saturates the plates and typically lasts 2-3 hours.

- Float Charge (5% capacity) – Compensates for natural discharge at about 13.2-13.4V. Modern smart chargers automatically enter this maintenance mode.

Advanced Charging Considerations

Professional maintenance requires attention to these often-overlooked factors:

- Temperature compensation – For every 10°F (5.5°C) above 77°F (25°C), reduce charge voltage by 0.03V per cell

- Equalization frequency – Flooded batteries need monthly equalization, AGM batteries only when imbalance exceeds 0.3V between cells

- Post-charge cooldown – Wait at least 30 minutes after charging before taking voltage readings for accuracy

Common Charging Mistakes to Avoid

These errors can cut battery life by 50% or more:

| Mistake | Consequence | Solution |

|---|---|---|

| Partial charging | Progressive sulfation | Always charge to completion |

| Using automotive chargers | Overcharging damage | Use golf cart-specific chargers |

| Charging when hot | Thermal runaway risk | Wait until below 100°F (38°C) |

Pro Tip: For lithium batteries, always use a charger with precise voltage control (±0.05V). Even slight overcharging can create dangerous thermal conditions in lithium-ion packs.

Implementing these charging best practices can extend your battery bank’s life from the typical 2-3 years to 5-7 years, providing significant long-term savings.

Battery Replacement Strategies: When to Upgrade and What to Choose

Understanding the optimal time for battery replacement and selecting the right technology can save hundreds of dollars annually. The decision involves evaluating performance metrics, cost-per-cycle calculations, and future-proofing your investment.

Performance Indicators for Replacement

These measurable signs indicate when batteries are beyond recovery:

| Metric | Healthy Range | Replacement Threshold | Test Method |

|---|---|---|---|

| Capacity | 90-100% of rated AH | Below 70% | 8-hour discharge test |

| Internal Resistance | 4-6 milliohms (new) | 25% increase | Impedance tester |

| Voltage Recovery | Returns to 12.7V within 1 hour | Takes >4 hours | Post-load voltage test |

Technology Comparison: Lead-Acid vs. Lithium

The modern golfer faces a critical choice between traditional and advanced battery technologies:

- Flooded Lead-Acid ($400-600/set)

- Proven reliability but requires monthly maintenance

- Lasts 4-5 years with perfect care

- Weight: 60-75 lbs each (affects cart performance)

- Lithium Iron Phosphate (LiFePO4) ($1,500-2,500/set)

- Maintenance-free with 2,000+ cycles

- 50% weight reduction improves range

- Built-in Battery Management System (BMS) prevents damage

Cost-Benefit Analysis

A municipal course switching to lithium documented:

- 36% reduction in energy costs (more efficient charging)

- 72% less downtime (no equalization cycles needed)

- 4-year ROI despite higher upfront cost

Future-Proofing Considerations

With evolving technology:

- Newer carts with regenerative braking work best with lithium

- Upcoming smart chargers will feature AI-driven optimization

- Federal incentives may soon apply to golf cart battery upgrades

Safety Note: Always dispose of old batteries properly – lead-acid recycling rates exceed 99% when using certified centers. Never mix battery chemistries in the same system.

Advanced Battery Monitoring Systems: Proactive Performance Management

Modern battery monitoring goes beyond simple voltage checks, offering real-time insights that can prevent 80% of common battery failures. These systems provide the data needed for truly predictive maintenance rather than reactive repairs.

Essential Monitoring Parameters

Professional-grade systems track these critical metrics simultaneously:

- State of Charge (SOC) – Percentage-based capacity measurement (accurate to ±1%)

- State of Health (SOH) – Tracks capacity fade and resistance growth over time

- Depth of Discharge (DOD) – Monitors cumulative stress from deep cycling

- Temperature Gradient – Detects hot spots indicating failing cells

System Integration Options

Choose monitoring solutions based on your cart’s complexity:

| System Type | Best For | Data Points | Sample Product |

|---|---|---|---|

| Basic Bluetooth | Single battery carts | Voltage/Temperature | Victron SmartShunt |

| CAN Bus Integrated | Modern fleet carts | Full battery analytics | Lynx Smart BMS |

| Cloud-Connected | Commercial operations | Fleet-wide comparison | TTI Power Pulse |

Implementation Best Practices

For optimal results:

- Calibrate monthly using a reference load to maintain accuracy

- Set custom alerts for your specific battery type’s thresholds

- Correlate data with charger logs to identify charging inefficiencies

- Track trends rather than individual readings for reliable predictions

Real-World Application

A 200-cart resort reduced battery replacement costs by 62% after implementing cloud monitoring that:

- Flagged carts with abnormal discharge patterns

- Automatically scheduled maintenance when SOH dropped below 80%

- Identified underperforming chargers by comparing recharge times

Technical Note: When installing shunts, always place them on the negative terminal and ensure current ratings exceed your cart’s maximum draw by at least 25%.

Comprehensive Battery Maintenance Program: A Systematic Approach

Implementing a structured maintenance program can extend golf cart battery life by 300% while reducing unexpected failures by 90%. This goes beyond basic care to address all aspects of battery health through scheduled interventions.

The Four Pillars of Effective Maintenance

| Pillar | Components | Frequency | Tools Required |

|---|---|---|---|

| Preventive | Terminal cleaning, water levels, torque checks | Weekly | Torque wrench, baking soda solution |

| Predictive | Capacity testing, voltage profiling | Monthly | Load tester, digital multimeter |

| Corrective | Equalization, desulfation, balancing | Quarterly | Smart charger, hydrometer |

| Analytical | Trend analysis, failure mode review | Annually | Battery monitoring software |

Advanced Maintenance Procedures

For commercial operations or high-value battery systems:

- Infrared Scanning – Detect hot spots indicating loose connections or failing cells

- Electrolyte Specific Gravity Testing – Use refractometers for flooded batteries (accuracy ±0.002)

- Microcycle Analysis – Identify damaging partial discharge/recharge patterns

Risk Mitigation Strategies

Address these common failure modes proactively:

- Thermal Runaway – Install temperature sensors with automatic charger cut-off

- Stratification – For flooded batteries, implement controlled overcharging quarterly

- Plate Corrosion – Maintain proper water levels and use only distilled water

Quality Assurance Protocol

Validate maintenance effectiveness through:

- Benchmarking against IEEE 1188 standards for VRLA batteries

- Documenting voltage recovery rates post-equalization

- Tracking mean time between failures (MTBF) monthly

Pro Tip: Create a “battery log book” documenting every service event, including photos of terminal conditions. This historical data becomes invaluable for troubleshooting recurring issues.

Commercial operators report this systematic approach reduces total cost of ownership by 40-60% compared to reactive maintenance strategies.

Conclusion: Maximizing Your Golf Cart Battery Performance

From parasitic drains to voltage imbalances and proper charging techniques, we’ve explored the seven key factors impacting your golf cart battery’s lifespan.

Remember that most premature failures stem from preventable issues like sulfation (65% of cases) or improper maintenance rather than manufacturing defects. The proactive strategies outlined – including systematic monitoring, temperature-aware charging, and scheduled equalization – can triple your battery’s service life.

Implement these solutions today: Start with a voltage imbalance check, then establish a monthly maintenance routine. Your batteries will reward you with reliable performance and significant long-term savings.

When in doubt, consult our detailed product recommendations for chargers and monitoring systems that take the guesswork out of battery care.

Frequently Asked Questions About Golf Cart Battery Drain

What’s the most common cause of overnight battery drain in golf carts?

Parasitic drains account for 75% of overnight discharge cases. These occur when accessories like lights, radios, or security systems continue drawing power when the cart is off.

A single LED light left on can drain 7+ amp-hours over 72 hours. Test by measuring current between the negative terminal and cable with a multimeter – anything above 50 milliamps indicates a problem.

How can I tell if my golf cart batteries are sulfated?

Sulfation shows through three key symptoms: 1) Rapid voltage drop under load (below 11V for 12V batteries), 2) Slow charging (taking 2-3x normal time), and 3) Visible white crust on lead plates. Use a smart charger with desulfation mode (like NOCO GEN5) to attempt recovery, but severe cases require replacement.

Why do my new golf cart batteries die so quickly?

Premature failure usually stems from:

1) Improper break-in (first 10 charges should be full cycles),

2) Voltage imbalance in packs (never mix old/new batteries), or

3) Undersized charger.

New batteries require 20+ full charge cycles to reach maximum capacity – partial charging during this period permanently reduces performance.

What’s the proper way to test golf cart battery health?

Conduct a three-part test:

1) Voltage test (12.7V+ at rest for 12V),

2) Hydrometer test (1.265 specific gravity for flooded batteries), and

3) Load test (maintains 10.5V+ under 50% load for 15 seconds).

Advanced users should measure internal resistance (shouldn’t exceed 6 milliohms for new batteries).

Can I use automotive battery chargers for my golf cart?

Never use standard car chargers – they lack the multi-stage charging golf cart batteries require. Golf cart chargers must: 1) Handle higher amp-hours (150-250AH vs car’s 50-80AH),

2) Include temperature compensation, and

3) Provide equalization modes.

Using automotive chargers causes undercharging and sulfation.

How often should I water my golf cart batteries?

Check flooded lead-acid batteries every 2-4 weeks, maintaining levels 1/4″ above plates. Water consumption increases with temperature – in 90°F+ weather, check weekly. Only use distilled water and never overfill (causes electrolyte dilution). Modern AGM and lithium batteries require no watering.

What’s the real cost difference between lead-acid and lithium batteries?

While lithium costs 3x upfront ($1,800 vs $600), the true cost comparison reveals:

1) Lithium lasts 5-7 years vs 2-3 for lead-acid,

2) 30% longer range per charge, and

3) Zero maintenance costs.

Most users achieve ROI in 2-3 years through extended lifespan and performance.

Why does my battery pack have one weak battery that keeps failing?

This “weak link” effect occurs when:

1) Batteries aren’t matched for age/capacity,

2) There’s uneven temperature exposure in the pack, or

3) Charging leads are improperly connected.

Always replace all batteries in a series pack simultaneously and ensure equal cable lengths for balanced charging.