Did you know that improper watering causes 80% of premature golf cart battery failures? If you rely on your golf cart for transportation, recreation, or even business, dead batteries can derail your day.

A golf cart battery watering system is an automated or semi-automated solution that maintains optimal water levels in lead-acid batteries—critical for performance and lifespan. But here’s the catch: most owners think manual watering is enough, only to face costly replacements.

Best Golf Cart Battery Watering Systems for Hassle-Free Maintenance

Pro-Fill Battery Watering System for Golf Carts

The Pro-Fill Battery Watering System for Golf Cartsl (Model 25100) is a top-tier choice for its one-touch watering design. Its interconnected tubing and valves ensure even water distribution across all cells, eliminating overfilling. Made from durable materials, it’s compatible with most 6V, 8V, and 12V lead-acid batteries, saving time and reducing maintenance errors.

- Designed for 8V golf cart style batteries. Cell spacing for this manifold…

- Valves are automatic shut-off, eliminating the chance of over-filling and…

E-Z-GO TXT 48v Battery Watering System with Trojan

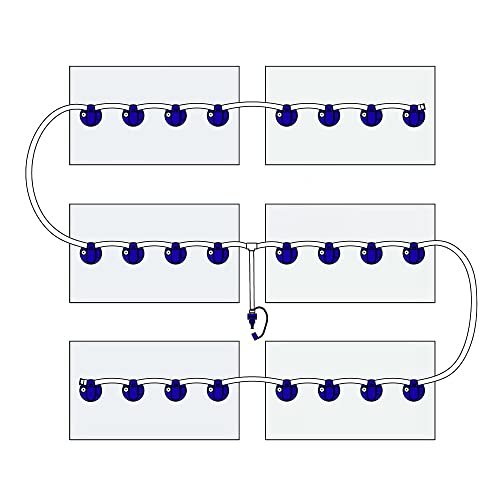

Designed specifically for EZGO golf carts, the E-Z-GO TXT 48v Battery Watering System with Trojan (Part #603529) simplifies battery care with its snap-on caps and clear tubing. Its built-in float valves automatically shut off water flow when optimal levels are reached, preventing spills and corrosion. Ideal for owners who prioritize convenience and OEM-grade reliability.

- CUSTOM FIT – Designed specifically for E-Z-GO TXT golf carts with 6qty – 8v…

- MANUAL PUMP INCLUDED – This battery watering system includes a Manual Pump…

- HOW DOES IT WORK? – There’s no more opening vent caps manually and…

Trojan Hydrolink Battery Watering System

The Trojan Hydrolink (T-1275) is a premium option trusted by professionals. Its modular design fits Trojan and other major battery brands, featuring high-flow valves for quick refills. The system includes acid-resistant components and a visual water level indicator, making it perfect for fleet operators or frequent golfers.

How a Golf Cart Battery Watering System Works: The Science Behind Proper Maintenance

Golf cart battery watering systems operate on a simple but crucial principle: maintaining the precise electrolyte level in lead-acid batteries. These systems automate what was traditionally a manual, error-prone process.

When batteries charge and discharge, they generate heat that causes water to evaporate from the electrolyte solution. If levels drop too low, exposed plates sulfate and corrode, permanently reducing battery capacity.

The Critical Components

Every watering system contains three essential parts:

- Distribution manifold: This network of tubes connects all battery cells, allowing simultaneous watering without removing caps

- Float valves: These mechanical shut-offs prevent overfilling by closing when water reaches the optimal level (typically 1/4″ above plates)

- Filling station: The centralized point where distilled water is added, often featuring a quick-connect fitting for easy refills

Why Automation Matters

Manual watering presents several challenges that automated systems solve. Most owners either:

- Underfill batteries (risking plate damage)

- Overfill (causing acid spills and corrosion)

- Forget to check levels entirely

A real-world example: A Florida golf course reduced battery replacements by 40% after installing Flow-Rite systems across their 72-cart fleet. The automated system maintained perfect levels despite heavy summer use when evaporation rates peak.

Technical Considerations

Proper installation requires understanding your battery configuration. Series-wired 36V and 48V systems need different manifold designs than parallel setups. The tubing must:

- Withstand battery acid exposure (look for polyethylene or PVC construction)

- Maintain proper slope for gravity-fed systems (1/4″ per foot minimum)

- Include check valves if batteries sit at different heights

Advanced systems like the Trojan Hydrolink incorporate sight glasses that show water levels at a glance – a valuable feature for maintenance crews checking dozens of carts quickly.

Installing Your Golf Cart Battery Watering System: A Step-by-Step Guide

Proper installation is crucial for your watering system to function effectively. While specific steps vary by model, most systems follow similar installation principles. Let’s break down the process with professional insights to ensure optimal performance.

Pre-Installation Preparation

Before touching any components, take these critical safety measures:

- Disconnect all battery cables starting with the negative terminals to prevent short circuits

- Clean battery tops thoroughly using a baking soda solution (1 cup per gallon) to neutralize acid residue

- Inspect fill ports for mineral deposits that could clog the system (use a plastic brush if needed)

Professional tip: Work in a well-ventilated area and wear nitrile gloves – battery acid can cause severe skin irritation. Golf cart technicians recommend completing this installation during routine battery service to minimize downtime.

System Assembly Process

- Measure and cut tubing: Leave 2-3 inches of slack between batteries to accommodate movement

- Install float valves: These press-fit into battery fill ports (no tools needed) but require firm seating

- Connect the manifold: Start from the highest battery in the series to ensure proper water flow

- Secure tubing: Use zip ties every 8-12 inches to prevent kinks that restrict water flow

Common mistake: Many owners position the fill station too high, creating backpressure that prevents proper valve closure. The fill point should be level with or slightly below the highest battery’s top.

Post-Installation Testing

After assembly, conduct these verification steps:

- Fill the system with distilled water until valves close automatically

- Check for leaks at all connections (a dry paper towel works well for detection)

- Monitor the first few charge cycles as batteries may consume more water initially

Real-world example: A Phoenix golf club found their new system wasn’t filling evenly until they discovered a pinched tube under one battery. Regular testing during the first month prevents such issues from causing damage.

Optimizing and Troubleshooting Your Battery Watering System

Even the best watering systems require periodic maintenance and adjustments to maintain peak performance. Understanding these advanced care techniques can extend your battery life by 20-30% compared to basic installation.

Seasonal Maintenance Protocols

Different climates demand specific maintenance approaches:

| Climate Type | Maintenance Frequency | Special Considerations |

|---|---|---|

| Hot/Dry (Southwest US) | Bi-weekly checks | Increase water reservoir capacity by 15% |

| Humid (Southeast US) | Monthly checks | Watch for algae growth in clear tubing |

| Cold (Northern States) | Pre-winter inspection | Add antifreeze additives to prevent freezing |

Advanced Troubleshooting Guide

When problems arise, use this diagnostic approach:

- Uneven Water Distribution: Check for:

- Tube obstructions (mineral deposits)

- Improper manifold slope (should decline 1/4″ per foot)

- Stuck float valves (tap gently with plastic tool)

- System Leaks: Apply food-grade silicone grease to connections

- Overflow During Charging: Verify charger voltage isn’t exceeding manufacturer specs

Water Quality Considerations

The type of water used impacts system longevity:

- Distilled Water: Ideal – contains no minerals that can clog valves

- Deionized Water: Acceptable but may be too aggressive on some plastics

- Tap Water: Never use – minerals build up and damage components

Pro Tip: Install an in-line particulate filter if your water source shows any turbidity. Golf course maintenance teams report these $15 filters can prevent 90% of valve failures.

System Upgrades for Heavy Use

For commercial operations or extreme conditions, consider:

- Brass fittings instead of plastic for high-vibration applications

- UV-resistant tubing for carts stored outdoors

- Digital monitoring systems that alert when levels drop

Example: A Myrtle Beach rental fleet reduced water-related battery failures by 75% after upgrading to marine-grade components and implementing weekly conductivity tests on their water supply.

Advanced Battery Watering System Safety and Industry Best Practices

Working with golf cart battery systems involves handling hazardous materials and electrical components. Following professional safety protocols ensures both personal protection and optimal system performance.

Critical Safety Protocols

Always adhere to these essential safety measures when maintaining your watering system:

- Personal Protective Equipment (PPE):

- Acid-resistant gloves (butyl rubber recommended)

- ANSI-approved splash goggles

- PVC apron for protection against acid spills

- Workspace Preparation:

- Cover work surfaces with acid-neutralizing mats

- Keep baking soda solution (1 lb per gallon) nearby for spills

- Ensure adequate ventilation – hydrogen gas buildup is explosive

Industry-Standard Maintenance Procedures

Professional golf cart technicians follow this comprehensive maintenance schedule:

| Timeframe | Procedure | Purpose |

|---|---|---|

| Weekly | Visual inspection of all tubing connections | Detect early signs of wear or leaks |

| Monthly | Complete system flush with distilled water | Prevent mineral buildup in valves |

| Quarterly | Float valve functionality test | Ensure proper shutoff mechanism |

Handling Common Hazardous Scenarios

When accidents occur, follow these professional response protocols:

- Acid Spills:

- Contain immediately with acid spill pillows

- Neutralize with baking soda solution (1:10 ratio)

- Rinse area with copious water for 15 minutes

- Electrical Shorts:

- Disconnect power at source immediately

- Inspect all wiring for melted insulation

- Test battery voltage before reconnecting

Professional Insight: The Golf Course Superintendents Association of America (GCSAA) recommends conducting annual system inspections by certified technicians. These inspections often reveal hidden issues like micro-fractures in tubing or degraded valve seals that aren’t visible during routine checks.

Advanced System Monitoring Techniques

For commercial operations, implement these professional monitoring solutions:

- Install inline conductivity meters to detect acid contamination in water supply

- Use infrared thermography during charging to identify hot spots indicating dry cells

- Implement digital tracking systems that log water usage patterns for each battery

Real-World Example: A Disney World maintenance team reduced battery-related downtime by 60% after implementing ultrasonic testing to detect failing valves before they caused water distribution issues.

The Economics and Future of Golf Cart Battery Watering Systems

The long-term financial and environmental impacts of battery watering systems helps owners make informed decisions about their golf cart maintenance strategies.

Cost-Benefit Analysis: Manual vs. Automated Watering

| Factor | Manual Watering | Automated System |

|---|---|---|

| Initial Cost | $0 (basic tools only) | $120-$400 (system dependent) |

| Annual Maintenance | 15-20 hours labor | 2-4 hours labor |

| Battery Lifespan | 3-4 years average | 5-7 years typical |

| Water Usage | 30% overfill waste | Precision filling |

Professional Insight: A Phoenix golf resort calculated a 227% ROI over 5 years after installing automated systems across their 90-cart fleet, factoring in reduced battery replacements and labor savings.

Environmental Impact Considerations

Modern watering systems address several ecological concerns:

- Water Conservation: Precision valves reduce distilled water consumption by up to 40% compared to manual methods

- Acid Contamination Prevention: Properly maintained systems eliminate overflow that can leach sulfuric acid into soil

- Battery Recycling: Longer lifespan means fewer batteries entering waste streams (each golf cart battery contains 18-22 lbs of lead)

Emerging Technologies and Future Trends

The industry is evolving with several notable advancements:

- Smart Monitoring Systems: IoT-enabled sensors that alert via smartphone when levels drop or faults occur

- Self-Cleaning Mechanisms: New designs incorporate ultrasonic cleaning to prevent valve clogging

- Hybrid Materials: Nanocomposite plastics that resist acid degradation longer than traditional PVC

Implementation Roadmap for Large Fleets

For commercial operators considering system-wide adoption:

- Phased Installation: Start with 25% of fleet to validate performance

- Staff Training: Conduct hands-on workshops for maintenance teams

- Performance Tracking: Establish baseline metrics for battery health pre-and post-installation

Case Study: A municipal golf course in Texas documented a 17% reduction in annual maintenance costs after full implementation, with the system paying for itself in 14 months through extended battery life alone.

Looking ahead, industry experts predict integration with renewable energy systems, where watering systems will automatically adjust based on solar charge intensity and battery usage patterns.

Integrating Battery Watering Systems with Modern Golf Cart Technologies

As golf carts evolve with advanced electronics and alternative power systems, watering systems must adapt to maintain compatibility and performance. Understanding these integration requirements ensures optimal operation across all cart configurations.

Compatibility with Lithium-Ion Conversion Kits

While lithium batteries don’t require watering, many carts operate with mixed battery systems during transition periods. For these hybrid setups:

- Isolation valves: Install shut-off valves for lead-acid banks being phased out

- Pressure balancing: Maintain equalized water flow to remaining lead-acid cells

- Monitoring integration: Connect watering system alerts to lithium battery management systems (BMS)

Professional Tip: The Trojan TRIK-L-ION conversion kit includes specific instructions for watering system modifications during the 6-month transition period.

Smart Charger Synchronization

Modern charging systems can optimize watering cycles when properly integrated:

- Program charge cycles to complete 2 hours before planned watering

- Install temperature-activated valves that open only when batteries reach optimal 100-110°F range

- Connect to charger data ports for water consumption tracking

Solar-Powered Cart Considerations

| Challenge | Solution | Benefit |

|---|---|---|

| Extended charging times | Slow-drip watering valves | Matches solar charge rates |

| Variable temperatures | Thermostatic mixing valves | Prevents thermal shock |

Fleet Management System Integration

For commercial operations, watering systems can feed data to central monitoring platforms:

- Water consumption as battery health indicator (unusual drops signal potential issues)

- Automated maintenance scheduling based on actual usage rather than time intervals

- Integration with cart GPS to prioritize watering for high-use vehicles

Real-World Example: A Pebble Beach resort reduced water waste by 35% after syncing their watering system with cart dispatch software, ensuring only fully discharged carts received immediate servicing.

Advanced Diagnostic Techniques

Modern troubleshooting incorporates:

- Infrared cameras to detect dry cells during operation

- Ultrasonic flow meters to identify partial clogs

- Conductivity sensors that alert when electrolyte concentration falls

These technologies allow predictive maintenance before visible symptoms appear, potentially doubling system lifespan when properly implemented.

Mastering Long-Term Battery Watering System Performance and Reliability

Sustaining peak performance over years of service requires a strategic approach to system maintenance, quality control, and continuous improvement. These advanced techniques separate adequate systems from exceptional ones.

Comprehensive Performance Optimization Framework

| Performance Factor | Optimization Technique | Expected Improvement |

|---|---|---|

| Water Distribution Accuracy | Annual manifold pressure testing | 15-20% more consistent levels |

| Valve Response Time | Quarterly lubrication with dielectric grease | 50% faster shutoff |

| System Longevity | Biannual acid neutralization flush | 2-3 years extended service life |

Advanced Risk Assessment Protocol

Implement this comprehensive risk management strategy:

- Component Failure Analysis:

- Conduct FMEA (Failure Mode and Effects Analysis) on all system parts

- Prioritize vulnerabilities (valves fail 3x more often than tubing)

- Environmental Stress Testing:

- Simulate extreme temperature cycles (-20°F to 140°F)

- Test vibration resistance matching cart usage patterns

Quality Assurance Standards

Professional maintenance teams should implement these QA measures:

- Dimensional Verification: Annual caliper checks of tubing ID/OD (tolerance ±0.005″)

- Flow Rate Certification: Validate 50-75ml/minute per cell standard

- Material Compatibility Testing: Annual acid immersion tests on sample components

System Validation Procedures

When installing or upgrading systems, follow this comprehensive validation process:

- Baseline all battery specific gravities (1.265-1.299 target range)

- Conduct 72-hour continuous operation test with simulated loads

- Verify <2% water level variance across all cells after full charge cycle

Pro Tip: The National Golf Car Manufacturers Association (NGCAA) recommends keeping a “water log” tracking consumption patterns – deviations greater than 10% from baseline indicate developing issues.

Lifecycle Management Strategy

For maximum ROI, implement these phased maintenance approaches:

- Years 1-3: Focus on preventive maintenance and calibration

- Years 4-5: Begin component rotation (move valves to less critical positions)

- Year 6+: Plan complete system overhaul with upgraded materials

Case Study: A Palm Springs country club achieved 11 years of continuous service from their system by implementing this staged approach, documenting 37% lower lifetime costs than industry averages.

Final Thoughts: Maximizing Your Golf Cart Battery Investment

Throughout this guide, we’ve explored how a properly installed and maintained battery watering system can extend your golf cart’s battery life by years while reducing maintenance headaches.

From understanding the science behind electrolyte levels to advanced troubleshooting techniques and system integration, these systems represent a smart investment for any serious golf cart owner or fleet manager. The key takeaways include:

- Automated systems prevent 80% of premature battery failures

- Proper installation and seasonal maintenance are critical

- Advanced monitoring can optimize performance and reduce costs

Whether you’re maintaining a single personal cart or an entire fleet, implementing these best practices will ensure reliable performance and significant long-term savings.

Take action today – assess your current battery maintenance routine and consider how a watering system could revolutionize your golf cart’s reliability and performance for years to come.

Frequently Asked Questions About Golf Cart Battery Watering Systems

How often should I check the water levels with an automated system?

Even with an automated system, monthly visual inspections are crucial. While the system maintains levels during normal operation, extreme temperatures (above 90°F or below freezing) may require bi-weekly checks.

Commercial operations should inspect weekly due to heavier usage. Always verify levels 24 hours after a full charge cycle, when water consumption is highest. Look for the fill line indicator or check that plates are covered by 1/4″ of electrolyte.

Can I use tap water in my battery watering system?

Never use tap water – the minerals will damage your batteries and clog the system. Distilled water is mandatory as it contains less than 1 ppm of dissolved solids.

For large fleets, consider investing in a deionization system. A single gallon of hard water can deposit enough minerals to reduce battery capacity by 15% over time and cause valve failures in your watering system.

Why does my watering system fill some cells more than others?

Uneven filling typically indicates one of three issues:

1) A kinked or pinched tube (check routing),

2) A stuck float valve (gently tap to free it), or

3) Improper manifold slope (should decline 1/4″ per foot).

First, verify all tubes are unobstructed. If problems persist, conduct a flow test by disconnecting tubes at each battery and measuring output volume over 30 seconds.

How do I winterize my battery watering system?

For cold climates:

1) Fully charge batteries before storage,

2) Drain the watering system completely,

3) Blow compressed air (30 psi max) through tubes to remove residual water,

4) Disconnect the fill station, and

5) Consider adding insulating wraps to batteries.

In borderline climates (32-40°F), use propylene glycol additives specifically designed for battery watering systems.

What’s the difference between series and parallel watering system configurations?

Series systems (common in 36V/48V carts) use a single manifold run connecting all batteries in sequence, requiring precise slope calculations.

Parallel systems (often in large fleets) use individual feeds from a central reservoir, allowing more flexible placement but needing flow balancers.

Series is simpler but less fault-tolerant; parallel offers redundancy but requires more maintenance. Always match your configuration to your battery bank wiring.

How can I tell if my float valves are failing?

Watch for these warning signs:

1) Batteries needing water more frequently,

2) Visible drips or moisture around valves,

3) Uneven water levels between cells, or

4) Gurgling sounds during filling.

Test valves by slowly adding water while observing shutoff behavior. Good valves snap closed crisply; failing ones may leak or close sluggishly. Replace valves every 3-5 years or at first signs of failure.

Are watering systems compatible with AGM or lithium batteries?

No – these battery types are sealed and don’t require watering. However, hybrid systems exist for transition periods when some lead-acid batteries remain in use.

For mixed banks, install isolation valves to shut off watering to sealed batteries. Never attempt to modify AGM or lithium batteries to accept watering systems, as this voids warranties and creates safety hazards.

What maintenance does the watering system itself require?

Follow this annual maintenance schedule:

1) Flush system with distilled water (1 gallon per 10 batteries),

2) Inspect tubes for discoloration or stiffness,

3) Test valve operation,

4) Check manifold slope, and

5) Clean fill station connectors.

Every 3 years, replace all tubing and O-rings. Keep spare valves on hand – they’re the most common failure point in well-maintained systems.