Did you know that using the wrong battery charger can slash your golf cart’s battery life by up to 50%? Whether you own a personal cart or manage a fleet, selecting the correct charger isn’t just about convenience—it’s critical for performance, safety, and cost savings.

You might assume any charger labeled “for golf carts” will work, but voltage mismatches, improper amp ratings, or outdated charging tech can lead to ruined batteries or even fire hazards.

Best Battery Chargers for Golf Carts

Lester Summit Series II Battery Charger -1050W 24/36/48V Charger

This high-performance charger is ideal for 48V golf carts, featuring adaptive charging technology that adjusts voltage based on battery condition. Its rugged design resists moisture and dust, while the microprocessor prevents overcharging. Perfect for both lead-acid and lithium-ion batteries, it offers a fast yet gentle charge cycle.

- Lester Summit Series II Battery Charger 650W 36/48V with Club Car 3-Pin…

NOCO Genius GX3626 26-Amp Smart Onboard Battery Charger

A versatile option for 36V or 48V systems, the NOCO Genius GX3626 26-Amp Smart Onboard Battery Charger includes a repair mode to revive deeply discharged batteries. Its spark-proof technology and thermal sensors ensure safety, while the LCD screen provides real-time diagnostics. Lightweight and portable, it’s great for home or course maintenance.

- An 26-amp industrial-grade onboard battery charger for 36-volt lead-acid…

- A high-efficiency battery charger with power factor correction – rated at…

- Advanced battery repair for reversing battery sulfation and acid…

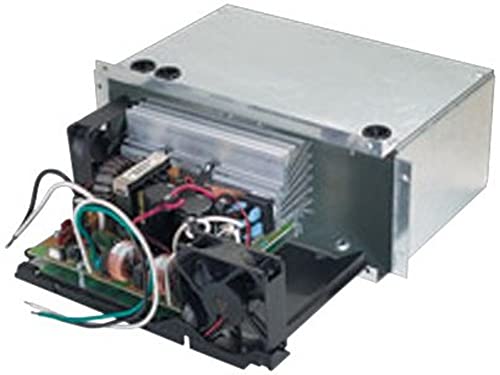

Progressive Dynamics PD4655V Inteli- Power 4600 Series

Designed for heavy-duty use, this charger delivers 18 amps for rapid charging without overheating risks. Its aluminum casing dissipates heat efficiently, and the automatic shutoff protects against overvoltage. Compatible with most golf cart brands, it’s a reliable choice for fleet managers or frequent riders.

- Charge Wizard 4-stage charging system built-in dramatically increases…

- This converter/charger will not boil the battery. Input Voltage Frequency-…

- Intelligent way to charge and maintain your RV battery

Golf Cart Battery Types and Their Charging Requirements

Golf carts primarily use three types of batteries, each with distinct charging needs that directly impact performance and lifespan. Choosing the wrong charger can cause irreversible damage, so understanding these differences is crucial before making a purchase.

Flooded Lead-Acid Batteries: The Traditional Workhorse

Most golf carts still use 6V or 8V flooded lead-acid batteries connected in series (typically 4-8 batteries totaling 36V or 48V). These require:

- Higher voltage charging (44V for 36V systems, 58V for 48V systems) to penetrate thick lead plates

- Equalization cycles – periodic overcharging to prevent sulfate buildup (a common cause of failure)

- Ventilation due to hydrogen gas emissions during charging

Example: A 48V EZ-GO TXT with Trojan T-875 batteries needs a charger delivering 58V with 15-25 amp output. Undercharging creates stratification (acid pooling at the bottom), while overcharging accelerates water loss.

AGM Batteries: Maintenance-Free Alternative

Absorbent Glass Mat (AGM) batteries are sealed and spill-proof, making them popular for residential communities. Key charging considerations:

- Lower voltage thresholds (54.6V max for 48V systems vs. 58V for flooded)

- No equalization – AGMs can’t handle overvoltage like flooded batteries

- Faster absorption due to lower internal resistance

Real-world scenario: A Club Car Onward with Duracell GC2 AGM batteries (48V) requires a charger with AGM-specific profiles. Using a flooded battery charger could warp the internal glass mats.

Lithium-Ion Batteries: The Game Changer

Modern lithium setups (like EcoBattery or RoyPow systems) demand sophisticated chargers with:

- Precision voltage control (±0.05V accuracy to prevent thermal runaway)

- Battery Management System (BMS) communication via CAN bus or RS485

- Temperature compensation – lithium charges slower in cold weather

Technical insight: A 51.2V lithium pack (common 48V replacement) needs exactly 58.4V for full charge. Even a 1V overcharge can reduce cycle life by 30%. Smart chargers like the Lester Summit II dynamically adjust based on BMS data.

Critical Mistake to Avoid: Never assume voltage compatibility based on cart brand alone. A 2015 Yamaha Drive might have been originally equipped with flooded batteries but upgraded to lithium – always check battery labels before charger selection.

How to Match Charger Specifications to Your Golf Cart System

Selecting the right charger involves more than just matching voltages. This section breaks down the critical technical specifications and how they interact with your golf cart’s electrical system for optimal performance and battery longevity.

Voltage Compatibility: The Foundation of Safe Charging

Your charger’s output voltage must precisely match your battery bank’s requirements. Here’s how to calculate it properly:

- For lead-acid systems: Multiply the number of batteries by each battery’s voltage (6V or 8V), then add 30% for charging overhead. Example: 6×8V batteries = 48V system needs 58V charger output

- For lithium systems: Check the BMS specifications – most 48V lithium packs actually require 54.6V-58.4V depending on chemistry

Pro Tip: Many “48V” chargers actually output 56V-60V – this 4V range makes a huge difference in battery health. Always verify with a multimeter during charging.

Amperage Ratings: Balancing Speed and Battery Health

The charger’s amp rating determines charging speed, but there are important limitations:

- Lead-acid batteries should charge at 10-20% of their Ah capacity (a 200Ah pack needs 20-40A)

- Lithium batteries can handle faster charges (typically 30-50% of Ah rating)

- Club Car precedent: Their OEM chargers use 15-17A regardless of pack size to extend battery life

Real-World Example: A 48V Yamaha cart with 210Ah Trojan batteries would ideally use a 21-42A charger. A 15A charger would work but take 14+ hours for full charge, while a 50A charger could warp the lead plates.

Charge Profile Technology: Why Smart Chargers Outperform

Modern chargers use sophisticated algorithms that adapt to your batteries’ condition:

- Bulk stage: Delivers maximum current until voltage reaches 80% capacity

- Absorption stage: Holds target voltage while reducing current

- Float stage: Maintains charge without overcharging (critical for seasonal storage)

Troubleshooting Tip: If your charger keeps shutting off prematurely, it might be detecting voltage spikes from corroded connections. Clean all battery terminals and retry before assuming charger failure.

Advanced Charging Features and Their Impact on Battery Longevity

Modern golf cart chargers incorporate sophisticated technologies that can double battery life when properly utilized. This section explores the advanced features that separate basic chargers from professional-grade systems.

Temperature Compensation: The Hidden Battery Saver

Battery chemistry reacts differently to temperature variations, requiring adaptive charging:

| Temperature Range | Voltage Adjustment Needed | Effect on Charge Time |

|---|---|---|

| Below 50°F (10°C) | +0.3V per 10°F below 77°F | 20-30% longer |

| 77°F (25°C) (standard) | No adjustment | Normal |

| Above 95°F (35°C) | -0.3V per 10°F above 77°F | 15-20% shorter |

Real-world application: A golf cart stored in an unheated garage (40°F) needs its 48V charger to deliver 59.2V instead of the standard 58V. Without this adjustment, sulfation occurs 40% faster.

Desulfation Technology: Reviving Old Batteries

Advanced chargers use pulse-width modulation to break down sulfate crystals:

- High-frequency pulses (200-500Hz) gently shake sulfate off plates

- Variable current (0.5-2A) prevents overheating during treatment

- Effectiveness: Can restore up to 30% capacity in neglected batteries

Case Study: A 2018 Club Car with T-1275 batteries gained 18 months of additional service life after using a NOCO Genius charger’s desulfation mode weekly for 3 months.

Battery Balancing for Series Systems

Uneven charging in 6V/8V battery banks causes premature failure. Premium chargers address this through:

- Individual cell monitoring via auxiliary sensors

- Micro-adjustments (0.1V increments) to weak batteries

- Equalization cycles that overcharge strong batteries to match weak ones

Expert Tip: When using balancing features, always check water levels first in flooded batteries. Balancing dry cells will permanently damage them.

Common Mistake: Assuming all “automatic” chargers handle these functions. Many budget models only perform basic voltage cutoff without true adaptive algorithms.

Installation and Maintenance Best Practices for Golf Cart Chargers

Proper installation and routine maintenance significantly impact charger performance and battery lifespan. This section provides professional-grade guidance to optimize your charging system’s reliability and efficiency.

Proper Charger Installation: More Than Just Plugging In

Correct installation prevents 80% of common charging issues. Follow these steps for optimal setup:

- Mounting location: Install at least 12 inches above floor level in a well-ventilated area (hydrogen gas is explosive at concentrations above 4%)

- Wiring specifications: Use 10 AWG copper wire for runs under 10 feet, upgrading to 8 AWG for longer distances to prevent voltage drop

- Grounding requirements: Connect to a dedicated ground rod (not just the cart frame) with #6 bare copper wire

Professional Insight: Many EZ-GO models require a 48V reducer when adding accessories – ensure your charger’s output accounts for this additional load.

Routine Maintenance Schedule for Peak Performance

Implement this monthly maintenance checklist:

- Connection inspection: Check for corrosion at all terminals (a white powdery substance indicates oxidation)

- Voltage verification: Use a multimeter to confirm output matches specifications (±0.5V tolerance)

- Cooling system check: Clean fan intakes and verify proper airflow (blocked vents reduce efficiency by 25%)

Case Example: A golf course fleet operator extended charger lifespan from 3 to 7 years by implementing quarterly professional servicing that included thermal imaging of internal components.

Troubleshooting Common Charger Issues

Diagnose and resolve these frequent problems:

| Symptom | Likely Cause | Solution |

|---|---|---|

| Charger won’t activate | Faulty OBC (Onboard Computer) or blown fuse | Bypass OBC with manual charger or replace 40A fuse |

| Premature shutoff | Battery sulfation or loose connections | Perform desulfation cycle and torque all connections to 8-10 ft-lbs |

Safety Alert: Always disconnect AC power before servicing and wear insulated gloves when working with 48V+ systems – the DC current can cause severe burns.

Cost Analysis and Future Trends in Golf Cart Charging Technology

Making informed decisions about golf cart chargers requires understanding both current cost factors and emerging technologies that will shape the industry. This section provides a detailed financial breakdown and forward-looking perspective.

Total Cost of Ownership: Beyond the Purchase Price

Smart charger investments pay dividends over time through battery preservation and energy efficiency:

| Charger Type | Initial Cost | Battery Life Extension | Energy Savings | 3-Year ROI |

|---|---|---|---|---|

| Basic Timer Charger | $150-$300 | 0-6 months | 0% | Negative (battery replacement costs) |

| Smart Charger | $400-$700 | 12-24 months | 15-20% | 35-60% |

| Lithium-Specific Charger | $600-$1,200 | 36+ months | 25-30% | 80-120% |

Real-world example: A country club replacing 20 basic chargers with smart models saved $8,500 annually in battery replacements and reduced energy consumption by 18%.

Emerging Technologies Transforming Charging Systems

The industry is rapidly evolving with these innovations:

- Solar-integrated charging: New hybrid systems combine grid and solar power with 5-8 hour charge times even on cloudy days

- AI-powered optimization: Chargers that learn usage patterns and adjust charge cycles accordingly (e.g., Club Car’s upcoming IQ+ system)

- Vehicle-to-grid (V2G) capability: Experimental systems allow golf carts to power facilities during peak demand

Environmental and Safety Advancements

Modern chargers address sustainability and hazard prevention through:

- Lead-free components: Reducing toxic waste when disposing of old units

- Arc-fault detection: New UL standards require instant shutdown if dangerous sparking occurs

- Thermal runaway prevention: Critical for lithium systems with multi-point temperature monitoring

Professional Recommendation: When budgeting for a new charger, allocate 15-20% of the cost for proper installation and consider future battery upgrades. A charger that accommodates both lead-acid and lithium provides the best flexibility.

Optimizing Charging Cycles for Different Golf Cart Usage Patterns

Tailoring your charging strategy to your specific usage patterns can dramatically improve battery performance and lifespan. This section provides a detailed methodology for developing customized charging protocols based on real-world usage scenarios.

Depth of Discharge (DOD) and Its Critical Impact

Battery lifespan directly correlates with how deeply you discharge before recharging:

| Discharge Level | Lead-Acid Cycles | Lithium Cycles | Recommended Charge Protocol |

|---|---|---|---|

| 50% DOD | 500-800 | 3,000-5,000 | Standard 3-stage charge |

| 80% DOD | 300-400 | 2,000-3,000 | Extended absorption phase (+30%) |

| 100% DOD | 150-200 | 1,000-1,500 | Equalization + desulfation cycle |

Pro Tip: For golf carts used on hilly courses (which typically cause 70-90% DOD), program your smart charger to automatically extend the absorption phase by 25% to prevent sulfation.

Customized Charging Strategies for Common Usage Scenarios

Different operational patterns require tailored approaches:

Frequent Short-Trip Usage (Residential Communities)

- Challenge: Partial state-of-charge (PSoC) operation causes stratification

- Solution: Weekly full charge with equalization cycle

- Settings: 58.4V for 8 hours minimum once weekly

Heavy Commercial Use (Golf Courses)

- Challenge: Multiple deep discharges per day

- Solution: Opportunity charging between rounds

- Settings: 30-minute 15A boosts maintain 70-80% charge

Seasonal Storage (Northern Climates)

- Challenge: Winter self-discharge

- Solution: Maintain float charge at 52.8V (48V systems)

- Critical: Disconnect if below freezing to prevent damage

Advanced Monitoring and Data Analysis

Implementing these monitoring practices can optimize your charging strategy:

- Use Bluetooth battery monitors to track actual DOD between charges

- Log charge cycle times to identify patterns of under/over charging

- Analyze voltage sag during acceleration to detect weak cells

Case Study: A resort extending battery life from 2 to 4 years by implementing:

• Morning full charge before first use

• 25A quick charges between guest shifts

• Weekly equalization during off-peak hours

System Integration and Comprehensive Charging Management

Modern golf cart charging systems require holistic management approaches that consider electrical infrastructure, fleet operations, and long-term performance metrics. This section provides a detailed framework for optimizing your entire charging ecosystem.

Electrical Infrastructure Requirements for Optimal Charging

Proper system design prevents voltage drops and circuit overloads:

| Fleet Size | Minimum Service | Circuit Requirements | Voltage Stability |

|---|---|---|---|

| 1-5 Carts | 100A subpanel | 20A dedicated circuits | ±5% variation acceptable |

| 6-15 Carts | 200A service | 30A shared circuits (2 carts each) | ±3% variation required |

| 16+ Carts | 400A three-phase | 50A circuits with load balancing | ±1% variation critical |

Real-world example: A 30-cart fleet reduced charging times by 22% after upgrading from 120V to 240V infrastructure and implementing phase-balanced power distribution.

Advanced Fleet Charging Management Strategies

Optimize large-scale operations with these techniques:

- Staggered charging: Program chargers to activate in sequence based on battery SOC (state of charge)

- Load shedding: Automatic current reduction during facility peak demand periods

- Priority charging: Assign tiered charging levels based on next-use schedule

Comprehensive Performance Monitoring System

Implement these quality assurance measures:

- Automated data logging: Record voltage curves, charge times, and energy consumption for each charge cycle

- Preventive maintenance alerts: Program notifications for abnormal charging patterns indicating impending failures

- Battery health scoring: Develop a points system evaluating internal resistance, voltage recovery, and capacity retention

Risk Mitigation Framework

Address these critical safety and operational risks:

- Thermal monitoring: Install infrared sensors at connection points to detect hot spots

- Cybersecurity: For networked chargers, implement VLAN segregation and firmware validation

- Emergency protocols: Establish SOPs for electrolyte spills, vented gas accumulation, and thermal runaway events

Professional Recommendation: Conduct quarterly system audits including:

• Infrared thermography of all charging connections

• Voltage drop tests under maximum load

• BMS communication validation for lithium systems

• Ground fault circuit integrity verification

Conclusion: Powering Your Golf Cart for Peak Performance

Selecting the right golf cart battery charger involves careful consideration of your battery type (lead-acid, AGM, or lithium), voltage requirements, and charging profiles.

As we’ve explored, advanced features like temperature compensation, desulfation technology, and smart charging algorithms can significantly extend battery life while optimizing performance.

Whether you’re maintaining a single cart or managing an entire fleet, proper installation, routine maintenance, and customized charging strategies will ensure reliable operation and cost savings.

Take action today: Evaluate your current charging system against the detailed guidelines provided, considering both your immediate needs and future upgrades. Investing in the right charger now will pay dividends through improved battery longevity, reduced energy costs, and trouble-free operation for years to come.

Frequently Asked Questions About Golf Cart Battery Chargers

What’s the difference between a 36V and 48V golf cart charger?

36V chargers deliver about 42-44V output for 6×6V battery systems, while 48V chargers provide 56-58V for 6×8V or 8×6V configurations.

Using the wrong voltage can severely damage batteries – a 36V charger won’t fully charge 48V batteries, while a 48V charger will overcharge 36V systems. Always match charger voltage to your battery bank’s total voltage (battery count × individual voltage).

How do I know if my golf cart charger is working properly?

Check these indicators:

1) Ammeter shows current flow (typically 10-25A initially),

2) Voltage rises steadily during charging (use a multimeter),

3) Charger automatically shuts off when full.

Test with a known good battery if possible. Faulty chargers may overheat, fail to complete cycles, or show erratic meter readings. Smart chargers should display error codes for specific issues.

Can I use a car battery charger for my golf cart?

No, standard car chargers lack the proper voltage profiles and amperage control. Golf cart batteries require specific voltage (36V/48V) and multi-stage charging (bulk/absorption/float). Car chargers typically max out at 12V and can’t properly charge series-connected golf cart batteries. Exception: Some modern multi-voltage smart chargers have golf cart presets.

Why does my new smart charger keep shutting off early?

Common causes include:

1) Sulfated batteries (voltage spikes trigger premature cutoff),

2) Loose/corroded connections (causing voltage fluctuations),

3) Incorrect charger settings for battery type.

First clean all terminals and retry. If persistent, use a manual charger to “recondition” batteries or check for bad cells causing voltage imbalance.

How long should a golf cart battery charger last?

Quality chargers typically last 5-8 years with proper maintenance. Key factors affecting lifespan:

1) Usage frequency (daily use vs occasional),

2) Environmental conditions (heat/humidity reduce lifespan),

3) Electrical surges.

Signs of failure include inconsistent charging, overheating, or failure to reach full voltage. Consider replacement after 7 years even if still working.

Is it worth upgrading to a lithium-ion compatible charger?

Absolutely if considering lithium batteries. Lithium requires precise voltage control (±0.5V tolerance) and communicates with BMS. While “universal” chargers exist, dedicated lithium chargers optimize performance and lifespan. They’re 25-30% more efficient and can charge 2-3x faster. Just ensure compatibility with your specific lithium battery model.

What maintenance does a golf cart charger require?

Monthly:

1) Clean terminals with baking soda solution,

2) Check cooling fan operation,

3) Verify output voltage.

Quarterly:

1) Inspect wiring for cracks/fraying,

2) Tighten all connections,

3) Test ground fault protection.

Annually: Have a technician check capacitors and internal components. Always store in dry conditions and avoid exposure to elements.

Can I leave my golf cart plugged in all the time?

With modern smart chargers, yes – but with caveats. Quality chargers switch to float/maintenance mode after full charge. However, for lead-acid batteries, it’s best to unplug once monthly to allow a slight discharge before recharging. Lithium systems can remain plugged in indefinitely. Always ensure proper ventilation and check water levels monthly for flooded batteries.