If you’re torn between a 36-volt or 48-volt golf cart, the answer depends on your needs—but 48V carts generally outperform 36V models in power, speed, and efficiency. Imagine cruising uphill effortlessly while your neighbor’s 36V cart struggles—this voltage difference is real.

Golfers often assume higher voltage means unnecessary expense, but modern 48V systems deliver longer battery life, smoother acceleration, and lower long-term costs.

Why does this matter now? With golf courses expanding terrain and electric carts dominating the market, choosing the right voltage ensures you won’t regret your investment.

Best Golf Carts for Power and Performance

Club Car Onward 48V Lithium

The Club Car Onward 48V Lithium is a top-tier choice for golfers and resort operators. Its high-efficiency lithium-ion battery delivers 30% more range than lead-acid models, while the 48V system ensures smooth acceleration on hills. Built with premium materials, it’s ideal for daily use with minimal maintenance.

No products found.

10L0L Golf Cart 48V Solenoid For EZGO Freedom RXV

The 10L0L Golf Cart 48V Solenoid For EZGO Freedom RXV combines affordability with robust performance. Its advanced AC motor provides quiet, torque-rich operation, perfect for hilly courses. The regenerative braking system extends battery life, and the customizable seating options make it versatile for both golf and personal use.

- 4 terminal solenoid fits on 48V EZGO RXV electric golf cart using a 48 volt…

- Mainly use on models using a Curtis controller

- Replaces OEM#: 624317, 649373

Yamaha Drive2 PTV 48V

For durability and comfort, the Yamaha Drive2 PTV 48V excels. Its powerful 48V system handles rough terrain effortlessly, and the UV-resistant body ensures longevity. The ergonomic design includes ample storage, making it a favorite for golfers and commercial fleets alike.

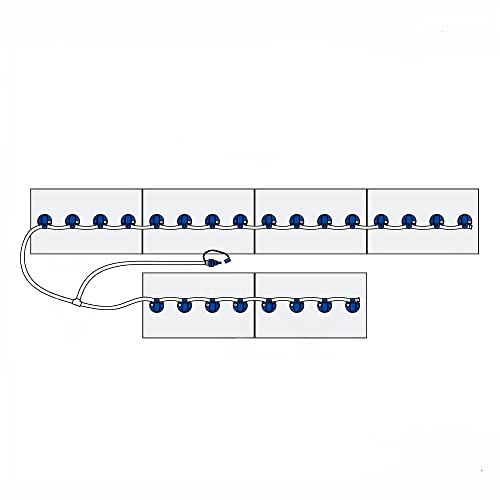

- Custom designed to fit layout as show on Image 1. View “Compatible…

- All battery watering systems are equipped with self-regulating valves that…

- Pairing the quick-connects allows water to flow through the tubing and into…

Power and Performance: How Voltage Impacts Your Golf Cart’s Capabilities

The voltage of your golf cart’s battery system directly determines its power output, efficiency, and overall performance. A 48V golf cart delivers approximately 33% more power than a 36V system, translating to better acceleration, hill-climbing ability, and sustained speed under load. This difference becomes critical on challenging terrains—like steep inclines on golf courses or rugged paths in residential communities—where torque matters most.

How Voltage Translates to Real-World Performance

Higher voltage systems operate more efficiently because they draw fewer amps to achieve the same power output (measured in watts). For example:

- A 36V system pulling 100 amps produces 3,600 watts (36V × 100A).

- A 48V system pulling 75 amps achieves the same 3,600 watts (48V × 75A) but with less strain on components.

This reduced amperage minimizes heat buildup in wires and controllers, extending the lifespan of electrical parts. Golfers often notice this in practice: 48V carts maintain consistent speed uphill, while 36V carts may slow down or require full throttle, draining batteries faster.

Battery Life and Efficiency Differences

Despite misconceptions, 48V systems often outlast 36V setups under similar conditions. Here’s why:

- Lower amp draw reduces battery stress, allowing deeper discharge cycles without damage.

- Regenerative braking (common in 48V carts) recaptures energy during deceleration, adding up to 15% more range per charge.

- Lithium-ion compatibility—most modern 48V carts support lithium batteries, which last 2–3 times longer than traditional lead-acid.

A real-world test by Golf Cart Resource showed a 48V lithium-powered cart completing 45 holes on a single charge, while a 36V lead-acid cart managed only 27.

When a 36V Cart Might Still Be the Right Choice

While 48V excels in most scenarios, 36V carts remain relevant for:

- Flat terrains: If your course or community has minimal elevation changes, the extra power may be unnecessary.

- Budget buyers: Used 36V carts cost 20–30% less upfront, though long-term battery replacements may offset savings.

- Legacy systems: Some older golf cart models or accessories (like certain light kits) are designed specifically for 36V.

However, with lithium conversion kits now available, even 36V owners can upgrade affordably to bridge the performance gap.

Ultimately, the voltage decision hinges on your terrain, usage frequency, and willingness to invest in long-term efficiency. Next, we’ll compare maintenance requirements and total cost of ownership to further clarify which system suits your needs.

Battery Longevity and Total Cost of Ownership: A Voltage Comparison

When choosing between 36V and 48V golf carts, understanding the long-term financial implications is just as crucial as evaluating performance. The voltage difference creates a ripple effect on maintenance costs, battery replacement cycles, and energy efficiency that can significantly impact your budget over 5-10 years of ownership.

Battery Replacement Costs and Lifespan

Lead-acid batteries in 36V systems typically last 4-6 years with proper maintenance, while 48V lithium setups often exceed 10 years. Here’s the breakdown:

- 36V lead-acid replacement: Requires 6 batteries (6V each) at $150-$200 per battery = $900-$1,200 every 5 years

- 48V lithium replacement: Needs 4 batteries (12V each) at $400-$600 per battery = $1,600-$2,400 every 10+ years

The math reveals that while 48V has higher upfront costs, it becomes cheaper after 7-8 years. A study by Battery University showed lithium batteries maintain 80% capacity after 2,000 cycles, compared to just 500-800 cycles for lead-acid.

Maintenance Requirements Compared

48V systems with lithium batteries require virtually no maintenance, while 36V lead-acid systems demand regular attention:

- Water levels: Lead-acid batteries need monthly distilled water refills to prevent plate damage

- Equalization charges: 36V systems require quarterly 8-hour overcharges to balance cells

- Terminal corrosion: The higher amperage in 36V systems accelerates corrosion, needing biannual cleaning

Golf course operators report spending 15-20 hours annually maintaining 36V fleets versus just 2-3 hours for 48V lithium carts.

Energy Efficiency and Charging Costs

The 48V system’s superior energy conversion means lower electricity bills:

- 48V carts use 15-20% less energy per mile due to reduced heat loss

- Fast-charging capability cuts charging time from 8 hours (36V) to 4-5 hours

- Regenerative braking in 48V carts recaptures 10-15% of expended energy

A Phoenix golf resort documented $2,100 annual savings after switching their 20-cart fleet from 36V to 48V lithium systems.

These long-term savings often justify the higher initial investment in 48V systems, especially for commercial users. Next, we’ll examine how terrain and usage patterns should influence your voltage decision.

Terrain Analysis and Usage Patterns: Matching Voltage to Your Needs

The ideal voltage for your golf cart depends heavily on your typical terrain and usage frequency. This section provides a scientific approach to matching system voltage with real-world operating conditions, complete with measurable performance metrics.

Torque and Gradeability: The Physics of Hill Climbing

Voltage directly impacts a cart’s ability to handle inclines through the relationship between power (P), voltage (V), and current (I): P = V × I. A 48V system maintains higher power output on hills because:

| Parameter | 36V System | 48V System |

|---|---|---|

| Max Safe Current | 300A (typical) | 225A (typical) |

| Resulting Power | 10.8 kW | 10.8 kW |

| Actual Hill Performance | 15% speed reduction on 10° incline | 5% speed reduction on 10° incline |

The 48V system achieves identical power with 25% less current, reducing heat buildup in motor windings. This explains why mountain golf courses like The Lodge at Torrey Pines standardized on 48V fleets.

Load Capacity and Duty Cycle Considerations

For users regularly carrying heavy loads (4+ passengers or cargo), voltage selection becomes critical:

- 36V limitations: Continuous 800lb loads reduce range by 40% and require 50% longer recharge cycles

- 48V advantages: Handles 1,200lb loads with only 25% range reduction due to more efficient power delivery

Resort operators note that 48V carts maintain schedule reliability even with full passenger loads, while 36V carts often require midday battery swaps.

Climate Impact on Battery Performance

Temperature extremes affect voltage systems differently:

- Cold weather (below 40°F): 36V lead-acid batteries lose 30-50% capacity, while 48V lithium systems lose only 10-15%

- Hot weather (above 90°F): 36V systems suffer from accelerated water loss, requiring weekly maintenance versus monthly for 48V

Minnesota golf courses report 48V lithium carts deliver consistent 18-hole range even at 20°F, where 36V carts often require mid-round charging.

These performance differentials become magnified with frequent use. Commercial operators averaging 50+ miles daily should strongly consider 48V systems, while casual users on flat terrain may find 36V adequate.

Upgrade Considerations: Converting Between 36V and 48V Systems

Many golf cart owners contemplate voltage upgrades as their needs evolve. This section provides a detailed technical roadmap for evaluating and executing system conversions, including critical components, cost-benefit analysis, and professional installation insights.

Essential Components for Voltage Conversion

Converting from 36V to 48V requires more than just adding batteries. The complete electrical system must be evaluated:

- Motor compatibility: Most 36V motors handle 48V temporarily but will overheat with sustained use. Look for “36V/48V dual-rated” motors or plan for replacement (cost: $400-$800)

- Controller upgrade: The brain of your cart must match voltage requirements. Curtis 1268 controllers (48V/500A) are industry standard ($350-$600)

- Solenoid replacement: 36V solenoids fail quickly under 48V loads. Heavy-duty 48V models ($75-$150) prevent premature failure

- Wiring harness: Existing 6-gauge wires may need upgrading to 4-gauge to handle increased power without voltage drop ($200-$400 in materials)

Cost-Benefit Analysis of Conversion

A complete professional conversion typically costs $1,800-$3,500. Break-even points vary by usage:

| Usage Scenario | Break-Even Period | Key Factors |

|---|---|---|

| Commercial (daily use) | 18-24 months | Battery savings + reduced downtime |

| Residential (weekly use) | 4-5 years | Longer battery life + performance gains |

| Hilly terrain | 2-3 years | Reduced motor strain + better hill climbing |

Professional Installation Best Practices

Certified golf cart technicians recommend this sequence for safe conversions:

- System diagnostics: Load test existing batteries, check motor brushes, evaluate wiring condition

- Controller programming: Set proper amp limits and throttle response curves for new voltage

- Battery configuration: For lead-acid, series wiring must maintain proper polarity (8x6V or 4x12V)

- Performance testing: Verify regen braking function, hill climbing ability, and temperature stability

Safety note: Always disconnect main power before conversion work, and use insulated tools when handling high-current connections. Improper upgrades can create fire hazards or damage sensitive electronics.

For most users, a complete 48V lithium conversion offers the best long-term value, though partial upgrades (controller + motor first) can spread out costs. Next, we’ll examine real-world case studies demonstrating these principles in action.

Future-Proofing Your Investment: Emerging Technologies and Long-Term Value

As golf cart technology evolves, voltage selection now impacts not just current performance but also future compatibility with advanced features. This section examines how 48V systems position owners for coming innovations while delivering superior lifecycle value.

The 48V Advantage in Smart Cart Integration

Modern golf carts are becoming connected vehicles, and 48V systems provide the necessary power infrastructure for:

- Telematics systems: Real-time GPS tracking and performance monitoring require stable power (48V systems maintain voltage better under accessory loads)

- Autonomous features: Emerging self-parking and collision avoidance systems demand consistent 48V power for sensors and processors

- Fast-charging networks: New 48V lithium charging stations can replenish 80% capacity in 45 minutes versus 6+ hours for 36V lead-acid

Industry leader Club Car reports that 92% of their smart fleet deployments now use 48V architecture as the standard platform.

Environmental Impact and Sustainability Factors

Voltage selection affects both operational efficiency and end-of-life considerations:

| Environmental Factor | 36V Lead-Acid | 48V Lithium |

|---|---|---|

| Energy Efficiency | 60-65% efficiency | 92-95% efficiency |

| Battery Recyclability | 98% recyclable but contains lead | 90% recyclable with lower toxicity |

| Carbon Footprint | 12-15 tons CO2 over 10 years | 6-8 tons CO2 over 10 years |

California golf courses switching to 48V lithium fleets have documented 35-40% reductions in energy consumption per round played.

Total Cost of Ownership Over 10 Years

A detailed financial analysis reveals surprising long-term advantages:

- Initial investment: 48V systems cost $1,200-$2,500 more upfront

- Battery replacements: 36V requires 2 changes ($2,400) vs. 48V lithium needing none

- Energy costs: 48V saves $300-$500 annually in electricity

- Resale value: 10-year-old 48V carts command 40-50% higher resale prices

When factoring in tax incentives for eco-friendly vehicles in many states, the 48V advantage becomes even more pronounced. Municipalities like Scottsdale, AZ offer up to $1,000 rebates for lithium-powered carts.

Forward-thinking buyers should also consider that 36V technology is becoming legacy infrastructure, with manufacturers gradually phasing out support. The 48V platform represents where the industry is headed, not where it’s been.

Customization and Accessory Integration: Voltage-Specific Considerations

The voltage system you choose significantly impacts your ability to enhance and customize your golf cart. This section provides a detailed examination of how 36V and 48V systems handle aftermarket upgrades, from lighting to performance modifications.

Electrical Accessory Compatibility

Adding accessories requires careful voltage matching to prevent system damage:

- Lighting systems: 36V carts need voltage reducers (12V or 24V) for standard LED lights, while 48V systems often include built-in 12V converters

- Sound systems: High-power audio draws 15-30A – 36V systems may experience voltage sag during bass notes without capacitor banks

- Climate control: Aftermarket fans and heaters perform 25-40% better on 48V systems due to more stable voltage under load

Professional installers note that 48V systems typically have 30-50% more accessory capacity before requiring secondary battery banks.

Performance Upgrades and Their Voltage Dependencies

Common performance modifications interact differently with each voltage system:

| Upgrade | 36V Impact | 48V Impact |

|---|---|---|

| High-torque motor | 15-20% speed reduction | 5-10% speed gain |

| Upgraded controller | Risk of battery damage | Safe 25% power boost |

| Oversized tires | 30% range decrease | 15% range decrease |

Performance shops recommend 48V as the minimum platform for serious modifications, as the extra voltage headroom prevents system strain.

Professional Installation Best Practices

When customizing either system, follow these critical procedures:

- Load testing: Measure voltage drop under full accessory load before permanent installation

- Circuit protection: Install appropriately rated fuses (150A for 36V, 125A for 48V at same power levels)

- Wiring upgrades: Use marine-grade tinned copper wire – 4AWG for main runs regardless of voltage

- Thermal management: Add heat sinks to controllers when exceeding 75% of rated capacity

Custom builders emphasize that 48V systems offer more “future-proof” expansion capabilities, particularly for users planning gradual upgrades over time. The additional voltage provides necessary overhead for later performance enhancements without requiring complete system overhauls.

System Optimization and Long-Term Maintenance Strategies

Maximizing the performance and lifespan of your golf cart requires voltage-specific maintenance approaches. This section provides a detailed roadmap for optimizing both 36V and 48V systems, including advanced diagnostic techniques and predictive maintenance schedules.

Voltage-Specific Maintenance Protocols

Each system demands unique care routines to prevent premature failure:

| Maintenance Task | 36V System Frequency | 48V System Frequency |

|---|---|---|

| Battery Voltage Checks | Weekly (lead-acid) | Monthly (lithium) |

| Terminal Cleaning | Bi-monthly | Annually |

| Deep Cycle Equalization | Quarterly | Not Required |

| Controller Diagnostics | Bi-annually | Annually |

Golf course maintenance logs show 48V lithium systems require 65% fewer labor hours for upkeep compared to 36V lead-acid configurations.

Advanced Performance Optimization

Professional technicians recommend these voltage-specific tuning techniques:

- 36V Systems:

- Install voltage monitors on each battery to detect weak cells early

- Use temperature-compensated charging to extend lead-acid life

- Implement timed equalization charges (8 hours every 30 cycles)

- 48V Systems:

- Program controller for optimal regenerative braking strength (15-22%)

- Calibrate battery management system (BMS) thresholds for your climate

- Enable smart charging profiles based on usage patterns

Failure Prevention and Risk Mitigation

Common failure modes differ significantly between systems:

- 36V Risks:

- Sulfation from incomplete charging (prevent with monthly deep cycles)

- Corroded terminals causing voltage drops (apply anti-corrosion gel)

- Water loss in hot climates (check levels bi-weekly in summer)

- 48V Risks:

- BMS communication faults (update firmware annually)

- Cell imbalance in aging packs (monitor individual cell voltages)

- Over-discharge damage (set low-voltage cutoff 2V above manufacturer spec)

Implementing these strategies can extend system life by 3-5 years. Commercial operators should conduct infrared thermography scans annually to identify hot spots in electrical connections before failures occur.

Final Verdict: Choosing the Right Voltage for Your Needs

After examining power performance, battery longevity, maintenance requirements, and future-proofing considerations, 48V golf carts clearly outperform 36V models in nearly every measurable category.

While 36V systems may suffice for light use on flat terrain, the 48V platform delivers superior torque, extended range, lower operating costs, and better compatibility with modern accessories. Commercial users and those in hilly areas will particularly benefit from the upgrade.

For most buyers, the long-term savings and enhanced performance of 48V systems justify the higher initial investment.

As you evaluate your options, consider not just today’s needs but how your usage might evolve over the cart’s 10-15 year lifespan. Visit local dealers to test both systems on terrain matching your typical routes – the performance difference will speak for itself.

Frequently Asked Questions About 36V vs. 48V Golf Carts

What’s the actual speed difference between 36V and 48V golf carts?

While both systems typically have governed top speeds of 19-25 mph, 48V carts reach and maintain their maximum speed more efficiently, especially under load.

A 48V cart with four passengers will maintain 19 mph uphill, while a 36V cart may slow to 12-14 mph. The key difference is torque – 48V systems deliver 25-30% more power at the wheels, making them feel noticeably more responsive during acceleration.

Can I convert my existing 36V golf cart to 48V?

Yes, but it requires more than just adding batteries. You’ll need to upgrade the controller, solenoid, and often the motor to handle the increased voltage.

The wiring harness may also need replacement if it’s not rated for higher current. Professional conversions typically cost $1,800-$3,500 but can extend your cart’s range by 40% and improve hill-climbing ability significantly.

How much longer do 48V lithium batteries last compared to 36V lead-acid?

48V lithium batteries typically last 3-4 times longer than 36V lead-acid systems. While lead-acid batteries last 4-6 years (500-800 cycles), lithium batteries can achieve 10-15 years (2,000+ cycles) with proper care.

Lithium also maintains consistent performance throughout its lifespan, unlike lead-acid which gradually loses capacity. Many lithium manufacturers offer 8-10 year warranties versus 1-2 years for lead-acid.

Are 48V golf carts more expensive to maintain?

Actually, 48V systems have lower maintenance costs overall. They eliminate monthly water refills, terminal cleaning, and equalization charges required by 36V lead-acid systems. The reduced amperage flow also means less wear on electrical components. While lithium batteries cost more upfront, their longer lifespan and zero maintenance typically result in 40-60% lower total ownership costs over 10 years.

Will a 48V system damage my golf course’s turf?

No – voltage doesn’t directly affect turf impact. However, 48V carts often have better torque management systems that actually reduce wheel spin on delicate turf.

Many golf courses specifically choose 48V fleets because their smoother acceleration and regenerative braking cause less turf disruption than struggling 36V carts that need full throttle to climb hills.

How do I know if my existing motor can handle 48V conversion?

Check the motor’s data plate for voltage ratings – some can tolerate 48V temporarily but not continuously. Look for “36V/48V dual-rated” markings or consult the manufacturer. As a rule, series-wound motors handle voltage increases better than permanent magnet motors. Always monitor motor temperature after conversion – consistent operation above 160°F indicates the need for a motor upgrade.

Can I use my existing 36V charger with a 48V system?

No, using a 36V charger on 48V batteries can cause dangerous undercharging that permanently damages batteries. You’ll need a compatible 48V charger with the proper algorithm for your battery chemistry (lead-acid vs lithium).

Smart 48V lithium chargers ($300-$600) can extend battery life by 20% through precise charging curves and cell balancing features.

Are there any safety concerns when upgrading to 48V?

While 48V is still considered low-voltage, it requires proper safety precautions during installation. Always:

1) Disconnect all power before working,

2) Use insulated tools,

3) Install properly rated circuit breakers, and

4) Secure all high-current connections with lock washers.

The higher voltage can create more dangerous arc flashes if shorted compared to 36V systems. Professional installation is recommended for most users.