Did you know that over 2 million golf cart batteries are discarded annually in the U.S. alone? Many owners assume dead batteries are worthless—but they’re wrong.

While your golf cart’s lead-acid battery may no longer hold a charge, it’s still a valuable commodity for recyclers, scrap dealers, and even DIY enthusiasts. The question isn’t whether someone wants your dead battery, but who will pay the most for it.

You might think tossing old batteries is the only option, but hidden opportunities exist. From cash-for-scrap programs to eco-conscious refurbishers, a network of buyers is eager to take them off your hands.

Best Buyers for Dead Golf Cart Batteries

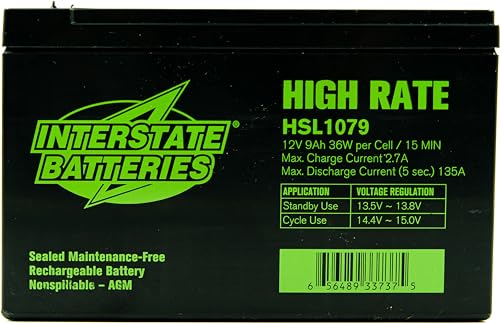

Interstate Batteries Recycling Program

Interstate Batteries offers a nationwide recycling program for dead golf cart batteries, including models like GC2, GC8, and GC12. They accept all lead-acid batteries, ensuring eco-friendly disposal and often providing store credit or discounts on replacements. Their network of drop-off locations makes it convenient.

- HIGH-RATE SLA BATTERY: When power interruption is unthinkable, think…

- HSL1079 BATTERY REPLACEMENTS: Download the Compatibility Guide below under…

- RECHARGEABLE, MAINTENANCE-FREE, SPILL-PROOF: Rechargeable,…

Gladson C-Thru 15Q Battery Recycling Tube

This company specializes in bulk purchases of used golf cart batteries, such as Trojan T-105 and US Battery US2200XC. They pay competitive rates per pound and handle logistics, including pickup services for large quantities. Ideal for golf courses or fleet owners with multiple dead batteries.

- Transparent 15-quart polycarbonate recycling collection tube perfect for…

- Colored funnel aperture and foot complete with standard or Recycle Across…

- Thick & clear polycarbonate exterior is hard-wearing and durable whilst…

UNNI Compostable Lawn and Leaf Liner Bags

Scrap yards like Sims Metal Management pay cash for lead-acid golf cart batteries (e.g., Duracell GC15). Prices fluctuate with market rates, but they offer immediate payment and no minimum quantity requirements. Call ahead to confirm current pricing and acceptance policies.

No products found.

Why Buyers Want Dead Golf Cart Batteries

Many golf cart owners are surprised to learn that their “dead” batteries still hold significant value. The secret lies in their composition—most golf cart batteries are lead-acid (flooded, AGM, or gel types), containing valuable materials that can be repurposed or recycled. Here’s exactly what happens to your old battery after you sell it:

The Hidden Value in “Dead” Batteries

A typical 6V or 8V golf cart battery contains:

- Lead plates (60-70% of weight) – Highly recyclable, often reused in new batteries

- Sulfuric acid electrolyte – Neutralized and converted to water or sodium sulfate

- Polypropylene casing – Melted down for plastic products

Even when a battery won’t hold a charge, these components retain 95%+ of their material value. For example, a single Trojan T-105 battery contains ~18 lbs of lead—worth $2-$4 at current scrap rates.

Primary Buyer Motivations

Buyers fall into three main categories, each with distinct goals:

- Recyclers (e.g., Battery Recyclers of America): Extract raw materials—lead prices fluctuate but typically net $0.15-$0.40 per pound. They follow EPA-certified processes to safely handle toxic components.

- Refurbishers: Some batteries fail due to sulfation (crystal buildup) that can be reversed. Companies like Battery Reconditioning Experts use desulfation chargers (e.g., NOCO Genius10) to restore partial capacity.

- Scrap metal yards: Pay by total weight—ideal when you have multiple batteries. Sims Metal Management reports golf cart batteries account for 12% of their lead intake.

Real-World Example: The Recycling Process

At an average recycling facility:

1) Batteries are crushed in a hammer mill

2) Plastic floats to the top for separation

3) Lead sinks and is melted into ingots

4) Acid is neutralized with baking soda

This closed-loop system recovers 99% of materials—the lead from your old battery could become part of a new one in under 60 days.

Pro Tip: Always check battery dates—buyers pay 20%+ more for batteries under 5 years old, as they’re more likely to be refurbished rather than scrapped.

How to Get the Best Price for Your Dead Golf Cart Batteries

Maximizing your return on dead golf cart batteries requires understanding market dynamics and proper preparation. The price you’ll receive depends on multiple factors that savvy sellers can optimize. Here’s how to turn your old batteries into maximum profit.

Key Factors That Determine Battery Value

Buyers evaluate batteries based on:

- Battery type: Flooded lead-acid (e.g., Trojan T-105) typically brings $8-$15 per battery, while AGM versions (e.g., Duracell GC2) may fetch 15-20% more due to cleaner handling

- Weight: Prices are often calculated by pound – standard 6V batteries weigh 60-70lbs, with current lead prices around $0.18-$0.25/lb

- Condition: Batteries with intact cases and terminals command premium prices – cracked cases may be rejected or get lower rates

Step-by-Step Selling Process

Follow this professional approach:

- Prepare your batteries: Clean terminals with baking soda solution, dry completely, and secure loose caps on flooded models

- Gather documentation: Many recyclers require ID and will issue EPA-compliant disposal certificates – ask about this upfront

- Shop around: Prices vary significantly – check local scrap yards (e.g., SA Recycling), battery stores (Interstate), and online buyers (BatteryRecyclers.com)

- Consider volume: Selling 10+ batteries? Negotiate bulk rates – most buyers offer $1-$2 more per unit for pallet quantities

Proven Strategies for Higher Returns

Seasoned sellers recommend:

- Time your sale: Lead prices typically peak in Q1 as manufacturers restock

- Combine with other recyclables: Many yards pay better when you bring multiple items (copper, aluminum)

- Ask about core charges: Some retailers (like Batteries Plus) apply credit toward new purchases

Real-world example: A Florida golf course recently netted $1,872 for 144 dead batteries by waiting for a quarterly price surge and negotiating free pickup – 23% more than their initial offers.

The Science Behind Golf Cart Battery Recycling: Environmental and Economic Impacts

Understanding the technical processes and environmental regulations surrounding battery recycling helps sellers make informed decisions while contributing to sustainability efforts. This section breaks down the complex lifecycle of recycled golf cart batteries.

The Chemistry of Battery Breakdown

When a golf cart battery reaches recyclers, it undergoes precise chemical processing:

- Lead recovery: Molten lead (327°C melting point) separates from other components in smelting furnaces with calcium carbonate flux to remove impurities

- Acid neutralization: Sulfuric acid (H₂SO₄) reacts with sodium hydroxide (NaOH) to form non-toxic sodium sulfate (Na₂SO₄) and water

- Plastic purification: Polypropylene casings are washed with tetrachloroethylene to remove lead residue before pelletization

| Component | Recovery Rate | Reuse Application |

|---|---|---|

| Lead | 99.3% | New battery plates, radiation shielding |

| Plastic | 98.7% | Battery cases, garden furniture |

| Electrolyte | 100% | Water treatment, textile manufacturing |

EPA Regulations and Compliance

Legal recycling requires adherence to:

- RCRA Standards: Proper containment of lead dust (≤50μg/m³ air concentration) and acid runoff prevention

- OSHA Protocols: Workers must wear NIOSH-approved respirators (minimum P100 filters) when handling crushed batteries

- Transportation Rules: DOT Hazard Class 8 labeling required for shipping more than 12 batteries

Economic Multiplier Effect

The recycling industry creates value at multiple levels:

- Local impact: Each ton of recycled lead generates 2.3 local jobs (Battery Council International data)

- Energy savings: Recycled lead requires 35-40% less energy than virgin lead production

- Market stability: Recycled materials account for 60% of US lead supply, buffering price volatility

Expert tip: Look for R2v3 or e-Stewards certified recyclers – they maintain 0.5% maximum material loss rates versus 3-5% at uncertified facilities.

Advanced Selling Strategies: Maximizing Returns on Dead Golf Cart Batteries

Moving beyond basic recycling, sophisticated sellers can implement specialized techniques to significantly increase their returns.

Battery Grading System for Optimal Pricing

Professional buyers classify batteries into three tiers:

- Grade A (Premium): Batteries under 4 years old with intact cases and measurable voltage (≥4V for 6V batteries). These often sell for 25-30% more as they’re candidates for reconditioning.

- Grade B (Standard): Older batteries (5-7 years) with minor case damage but recoverable lead content. These typically fetch standard scrap rates.

- Grade C (Industrial): Severely damaged or leaking units that require special handling. Prices are usually 15-20% lower due to additional processing costs.

Specialized Sales Channels

Beyond scrap yards, consider these high-value outlets:

- Battery reconditioning workshops: Many small businesses seek batteries with recoverable cells. Advertise on platforms like BatteryReconditioningForum.com with detailed specs (voltage, water levels, plate condition).

- Solar power enthusiasts: DIY solar projects often repurpose golf cart batteries for off-grid storage. List on renewable energy marketplaces with capacity test results.

- Local battery swap programs: Some retailers like Sam’s Club offer trade-in bonuses when purchasing new batteries – often more valuable than straight scrap value.

Safety and Legal Best Practices

Professional handling requires:

- Proper storage: Keep batteries on polyethylene pallets in well-ventilated areas (minimum 5 air changes per hour) to prevent hydrogen gas accumulation

- Transport preparation: Neutralize terminals with anti-corrosion spray and use UN-approved containers (UN2794 for flooded batteries)

- Documentation: Maintain chain-of-custody records including battery weights, purchase receipts, and recycling certificates for tax purposes

Pro tip: Consider investing in a basic battery analyzer (like the Foxwell BT705) to test remaining capacity. Even “dead” batteries showing 20-30% capacity can command premium prices from certain buyers.

Real-world case: A Michigan golf course increased annual battery revenue by $1,200 by implementing grading, separating Grade A batteries for reconditioners, and timing sales to quarterly lead price peaks.

The Future of Golf Cart Battery Recycling: Emerging Trends and Technologies

The battery recycling industry is undergoing significant transformation, with new technologies and market forces reshaping how dead golf cart batteries are processed and valued. Understanding these developments helps sellers prepare for coming changes.

Technological Advancements in Battery Processing

Innovations currently revolutionizing recycling include:

- Hydrometallurgical extraction: New chemical processes using citric acid or EDTA solutions can recover 99.9% pure lead at lower temperatures (80-100°C vs traditional 327°C smelting)

- AI-powered sorting: Computer vision systems now automatically classify battery conditions with 98% accuracy, optimizing processing routes

- Closed-loop recycling: Some manufacturers (like Trojan) now offer programs where your old battery becomes raw material for their new products

| Technology | Adoption Rate | Impact on Seller Returns |

|---|---|---|

| Direct cathode recycling | 15% of facilities | Potential 8-12% price premium |

| Plasma separation | 5% of facilities | Higher purity materials = better rates |

| Mobile shredding units | Growing in rural areas | Reduces transport costs |

Market Forces Shaping Future Prices

Key factors influencing long-term valuation:

- Lithium-ion transition: As golf carts shift to Li-ion (expected 40% market penetration by 2028), lead-acid recycling capacity may concentrate among fewer specialists

- Carbon credit programs: New regulations may allow sellers to claim emissions credits – California’s AB 1509 proposes $12/ton CO2 equivalent for proper recycling

- Global lead demand: Renewable energy storage needs may increase lead prices (projected 3-5% annual growth through 2030)

Strategic Planning for Sellers

Forward-thinking approaches include:

- Diversifying buyers: Building relationships with both traditional recyclers and tech-forward processors

- Tracking battery histories: Maintaining detailed service records increases resale options as buyers value known maintenance histories

- Investing in testing equipment: Basic conductance testers ($150-300) can identify batteries with residual value beyond scrap

Expert insight: The Battery Council International predicts lead-acid golf cart batteries will maintain 60-65% market share through 2030 due to their recyclability advantage over lithium alternatives.

Specialized Handling and Transportation Protocols for Dead Golf Cart Batteries

Proper handling of dead golf cart batteries requires specific technical knowledge to ensure safety, regulatory compliance, and maximum value retention.

Advanced Preparation Techniques

Before transport or storage, batteries require careful preparation:

- Neutralization procedure: Mix 1 pound baking soda with 1 gallon water to neutralize terminal corrosion (pH should test 7-8 after application)

- Terminal protection: Apply non-conductive grease or commercial terminal protectors (like NO-OX-ID A-Special) to prevent arcing

- Case inspection: Use UV light (365nm wavelength) to detect hairline cracks not visible to naked eye

Professional Transportation Methods

For safe, legal transport:

- Container specifications: Use UN-approved, HDPE containers with minimum 2mm wall thickness and secure lid fasteners

- Load configuration: Stack batteries upright with rubber matting between layers (maximum 3 high for 6V batteries)

- Documentation requirements: Prepare EPA Form 8700-22 for shipments over 500 lbs, including battery chemistry details

Storage Optimization Strategies

For temporary storage:

- Environmental controls: Maintain storage area at 50-70°F with relative humidity below 60% to minimize self-discharge

- Safety systems: Install hydrogen gas detectors (set to alarm at 1% LEL) and explosion-proof ventilation

- Inventory management: Implement FIFO (First In, First Out) system with barcode tracking for optimal rotation

Special Case Handling

For damaged or leaking batteries:

- Containment protocol: Use polypropylene spill pallets with 110% containment capacity

- Personal protective equipment: Chemical-resistant gloves (Butyl rubber, minimum 14 mil thickness) and full-face shields required

- Emergency procedures: Maintain calcium gluconate gel for acid exposure and Class D fire extinguishers

Professional tip: For large quantities (50+ batteries), consider investing in a battery racking system with integrated neutralization drip pans – this can reduce handling time by 40% while improving safety.

Regulatory note: OSHA 1910.178(g) mandates specific training requirements for personnel handling more than 1,000 lbs of lead-acid batteries monthly.

Comprehensive Risk Management and Quality Assurance in Battery Recycling

Professional handling of dead golf cart batteries requires systematic risk assessment and quality control measures to ensure safety, regulatory compliance, and optimal financial returns.

Advanced Risk Assessment Matrix

Key risk factors and mitigation strategies:

| Risk Category | Probability | Impact | Mitigation Strategy |

|---|---|---|---|

| Lead exposure | Medium | High | Quarterly blood testing (OSHA 1910.1025), HEPA ventilation |

| Acid burns | High | Medium | Emergency showers within 10 seconds, pH-neutral stations |

| Fire/explosion | Low | Critical | Hydrogen monitors, spark-proof tools |

| Regulatory fines | Medium | High | Monthly compliance audits, digital recordkeeping |

Quality Assurance Protocols

To maximize battery value:

- Pre-sorting inspection: Use calibrated conductance testers (Midtronics EXP-1000) to identify batteries with residual capacity

- Material verification: XRF analyzers verify lead purity (minimum 99.97% for premium pricing)

- Documentation chain: Implement blockchain-based tracking for audit-proof recycling certificates

Performance Optimization Strategies

Advanced techniques include:

- Moisture control: Maintain 45-55% RH in storage to prevent terminal corrosion (saves 2-3% material loss)

- Inventory analytics: Predictive algorithms determine optimal selling times based on LME lead futures

- Process automation: Robotic palletizers can increase throughput by 150% while reducing handling injuries

Long-Term Maintenance Considerations

For sustainable operations:

- Employee training: Annual 40-hour HAZWOPER certification plus quarterly refreshers

- Equipment calibration: Monthly verification of scales (±0.1% accuracy) and testing equipment

- Facility upgrades: Concrete floors require epoxy coatings (minimum 12 mil thickness) to resist acid penetration

Industry benchmark: Top-tier recyclers maintain <1% material loss and achieve 99.9% regulatory compliance through these integrated systems.

Conclusion: Turning Dead Batteries Into Smart Opportunities

As we’ve explored, dead golf cart batteries represent far more than just waste – they’re valuable commodities with multiple redemption pathways. From scrap metal yards paying by the pound to specialized recyclers extracting premium materials, your old batteries hold tangible value.

We’ve covered the complete lifecycle: understanding battery composition, navigating buyer networks, maximizing returns through strategic selling, and complying with environmental regulations.

The market for used batteries continues evolving, with new technologies improving recycling efficiency and creating additional value streams.

Whether you’re an individual owner with a single battery or a facility manager handling dozens, applying these professional approaches can significantly increase your returns while contributing to environmental sustainability.

Take action today: Inventory your dead batteries, prepare them properly, and connect with the buyer that best matches your needs and volume.

Remember – that “dead” battery in your garage could be worth $15-$50 to the right buyer, and proper recycling keeps hazardous materials out of landfills. The perfect time to cash in is now, while lead prices remain strong and recycling technologies continue advancing.

Frequently Asked Questions About Selling Dead Golf Cart Batteries

What’s the difference between selling to scrap yards versus battery recyclers?

Scrap yards typically pay by total weight at current lead prices (about $0.18-$0.25/lb), while specialized battery recyclers may offer higher rates for intact batteries they can refurbish.

Recyclers like Battery Recyclers of America often pay 10-15% more for batteries under 5 years old with measurable voltage. Scrap yards are better for damaged batteries, while recyclers prefer units with potential for reconditioning.

How do I safely transport multiple dead golf cart batteries?

Use UN-approved containers (marked UN2794) with secure lids. Place batteries upright on rubber mats, separating layers with cardboard.

Never stack more than three high. For over 12 batteries, you’ll need hazardous materials placards. Always neutralize terminals with baking soda solution first, and transport in a well-ventilated vehicle – hydrogen gas buildup can be dangerous.

Why do some buyers reject batteries with cracked cases?

Cracked cases pose three major issues: acid leakage hazards, potential lead contamination, and difficulty in automated processing.

Most facilities charge $5-10 extra per cracked battery for special handling. However, some specialty recyclers like Gopher Resource will accept them at reduced rates (typically 20% less than intact units).

Can I get more money by disassembling the batteries myself?

We strongly advise against DIY disassembly due to extreme safety risks (acid burns, lead exposure). Professional recyclers use $500,000+ equipment to safely process batteries. Even if you extract lead plates, most buyers won’t purchase them due to contamination concerns. You’ll typically get better rates selling whole batteries to authorized recyclers.

How often do lead prices change, and when’s the best time to sell?

Lead prices fluctuate daily on the London Metal Exchange. Historically, prices peak in January-March (manufacturing restocking) and dip in summer.

Sign up for LME price alerts, and consider holding batteries when prices are below $0.90/lb. Large sellers (50+ batteries) can sometimes lock in futures prices through brokers.

What documentation should I request from the buyer?

Always get a detailed receipt showing weight, price per pound, and total payment. For environmental compliance, request an EPA Form 8700-22 (hazardous waste manifest) and a Certificate of Recycling. These documents prove proper disposal and may be needed for tax purposes or environmental audits.

Are lithium golf cart batteries worth recycling differently?

Absolutely. Lithium-ion batteries (like those in newer Club Car models) require specialized handlers due to fire risks. Companies like Call2Recycle offer free lithium battery recycling, but don’t pay for them.

However, some tech recyclers may purchase functional lithium packs for energy storage projects.

How can I identify if my “dead” battery has refurbishment potential?

Use a digital voltmeter – batteries showing 4.5V+ (for 6V) or 6V+ (for 8V) may be reconditionable. Check water levels (plates should be submerged) and look for white sulfate crystals on terminals. Batteries under 4 years old with these characteristics can fetch 25-40% more from refurbishers.